Concrete Tests – Part 2

The last article published on KOT’s Blog covered concepts such as: concrete, building pathologies, ultrasonic, tomography and pacometry for concrete structures.

This paper aims to discuss the following tests for concrete structures:

- Sclerometer;

- Extensometry;

- Accelerometry;

- Axial compressive strength;

- Carbonation.

Sclerometer

Sclerometer is a non-destructive test that measures concrete surface hardness, providing evaluation elements for the quality of hardened concrete. The equipment used is the reflection sclerometer.

The evaluation of surface hardness by reflection sclerometer consists of measuring and correlating the elastic energy conserved after the impact of a semispherical tip rod against the test area. This energy is usually presented in terms of the sclerometric index.

Sclerometer in practice

Basically, the several values measured during the concrete tests are registered, tabulated and used to calculate the final sclerometric index. With the proper statistical treatment, the final sclerometric index is used to correlate the characteristic compressive strength of the concrete tested.

Therefore, as mentioned before, in addition to concrete ultrasonic tests, sclerometry is particularly interesting for large and/or responsible structures commissioning, as are the cases of:

- Bridges;

- Overpasses;

- Tunnels;

- Equipment support, such as crushers, silos, mills, etc..

Due to its simplicity and execution speed, pacometry can also be used to determine regions to be further investigated by more precise methods.

Extensometry and Accelerometry

Extensometry and accelerometry are commonly used to monitor the structural response to the set of actions that they are subjected to.

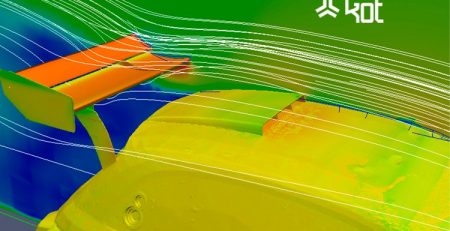

In structural calculation practice, stresses and strains can be obtained through the idealization of certain structural behaviors, the estimation of acting loads and knowledge of the material under analysis. These and other assumptions are also adopted for the computational representation of structures with Finite Element Method.

In this context, when needs arise about one of these factors, extensometry and accelerometry are some of the tools available to evaluate the real structural response of the asset. In general, they can be applied to concrete test when:

- You want to evaluate the structural behavior under a given load;

- You want to know the magnitude and behavior of a load over a certain period of time;

- You need to monitor the structural response to a special or exceptional action;

- You want to monitor the structural response to actions arising from its operation, as occurs in SHM.

In addition to the mentioned cases, the possibility of monitoring speeds, displacements, and structural defects, such as crack, makes it possible to know changes in the structural behavior and to raise the alarm about non-compliance with normative ultimate or service limit states. This last case is especially interesting for:

- Structures that support vibrating processes where the dynamic response of the assembly (equipment and structure) impairs the mechanical performance or causes damage to the structure;

- Bridges, overpasses, footbridges and structures where user discomfort is particularly relevant and needs to be monitored.

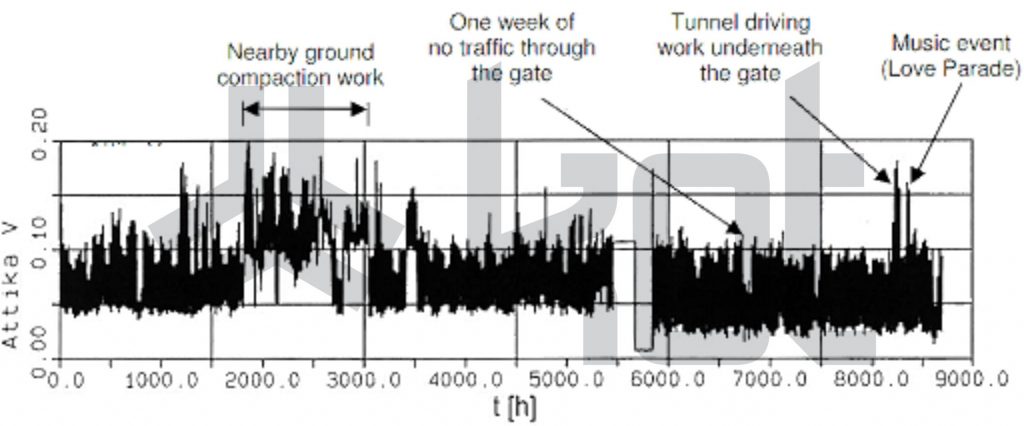

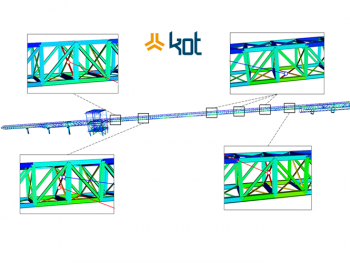

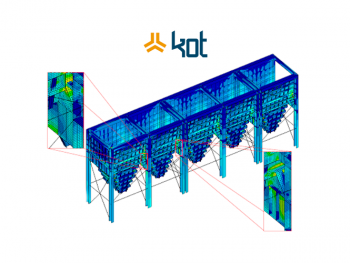

Figure 7 shows an example of the application of these methodologies for monitoring a structure of great responsibility.

Regarding other structural materials, extensometry in concrete pieces must be evaluated according to the material’s inhomogeneity, mechanical behavior of the reinforced pieces and the type of action or phenomenon to be investigated.

If you are interested in learning more about these methods and their applications, be sure to check out our blog series on extensometry and accelerometry:

- Basic Principles of Strain Gauges – Part 1;

- Basic Principles of Strain Gauges – Part 2;

- The basic principles of the use of accelerometers.

Axial compressive strength in specimens

Although estimated by non-destructive testing methods, the definition of concrete characteristic compressive strength in service occurs through the direct extraction of concrete samples from the structure. In this context, a concrete piece with standardized cross section, when broken in a press, allows the direct obtention of the stress at which failure occurs.

According to the applicable Brazilian standards, the definition of axial compressive strength in cores is useful in concrete testing for:

- Final acceptance of concrete in case of non-conformity of concrete compressive strength;

- Evaluation of structural safety of construction works in progress;

- Verification of structural safety in existing constructions, considering changes of use, accidents, partial collapse and other situations in which the compressive strength of concrete must be known.

Ideally, in addition to non-destructive concrete test results, compressive strength results are desirable to improve the overall understanding of the structure. Another advantage associated with core extraction is the availability of material for carbonation, contamination and concrete durability testing.

One of the risks associated with this process is piece embrittlement due to loss of section or reinforcement bar cutout. Thus, to prevent the irrecoverable embrittlement of the pieces, it is necessary to know the structural behavior complemented by pacometry tests. Figure 8 exemplifies the test specimen extraction procedure.

Carbonation front depth

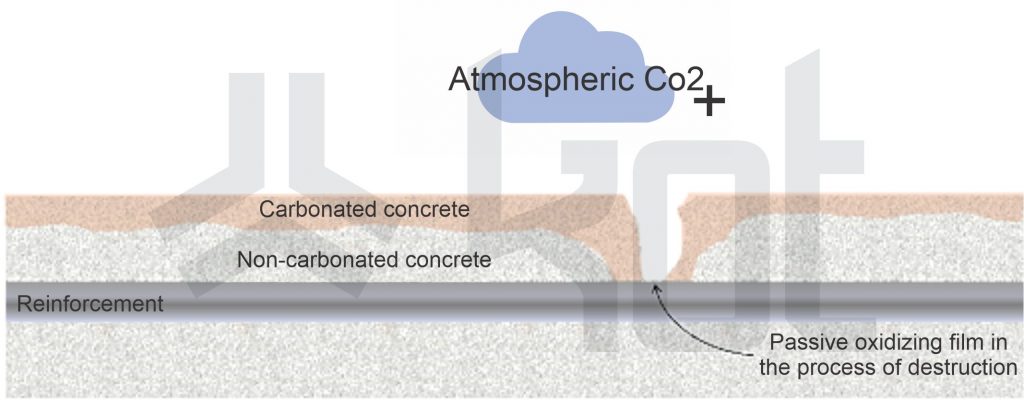

Concrete carbonation results from the action of atmospheric carbon dioxide (CO2) on hydrated cement. Among other factors, this phenomenon culminates in the reduction of concrete pH to values below 9, hydrogen concentration from which it becomes possible the onset of corrosion of the reinforcement bars of the structure, also known as depassivation.

The carbonation speed is a function of the carbon dioxide concentration in the environment, the porosity of the concrete and the presence of cracks in the piece. Beyond these factors, estimating the period required for reinforcement depassivation requires knowledge of the cover (concrete layer that covers the reinforcement) of the pieces. Figure 9 exemplifies the mechanism discussed.

Given this discussion, the knowledge of the carbonation front depth becomes interesting because the applicable set of standards understands by service life the period of time during which the structure maintains certain characteristics and does not require significant interventions.

Being one of the predominant deterioration mechanisms related to reinforcement, depassivation by carbonation of reinforcement is undesirable and difficult to recover.

In summary, the knowledge of the carbonation front depth in the structure becomes relevant since the depassivation by carbonation of the reinforcement indicates one of the references for the service life of concrete structures. Figure 10 presents results for this type of evaluation.

Conclusion

The correct interpretation of the anomaly manifestation mechanisms presented by concrete structures allows the safe operation and maintenance of the asset throughout its life cycle. In this process, concrete tests allow the best characterization of defects and their manifestation mechanisms.

For the diagnostic process it is also important to note the complementary role that several of these methodologies have between them and the need to understand the limitations and applications at the time of their choice.

Finally, as mentioned throughout the text, structural analysis and detailed visual inspection are also indispensable tools in this process. In this sense, KOT Engenharia has a team of specialists trained to interpret, perform and develop appropriate engineering solutions to boost your results.

Contact our team for more information!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] SOUZA, RIPPER. Patologia, recuperação e reforço de estruturas de concreto. São Paulo: Pini, 1998.

[2] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS – NBR 6118:

[3] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS – NBR 7680: Concreto – Extração, preparo, ensaio e análise de testemunhos de estruturas de concreto Parte 1: Resistência à compressão – 2015.

[4] IAEA. Guidebook on non-destructive testing of concrete strutures. Vienna: IAEA, 2002.

[5] SAMCO. F08a Guideline for the Assessment of Existing Structures. Berlim: SAMCO, 2006.

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS – NBR 7584: Avaliação da dureza superficial pelo esclerômetro de reflexão – Método de ensaio, 2012.

Leave a Reply