Success case: Structural Analysis of Modifications of Silos

Often, within the industry, we are faced with unexpected phenomena during operations: clogging, failures, poor distribution of materials and loads, among others. In order to approach these cases, a common and expensive solution is to acquire new machinery. On the other hand, to carry out a structural evaluation is, mostly, a less expensive solution, in which the problem is analyzed and modifications are proposed for the equipment already present in the company.

In this article you will learn more about how KOT Engenharia applied Structural engineering knowledge by proposing solutions for conditions of silos operations. If you are interested in reading more cases developed by KOT Engenharia, click here.

Structural analysis of silos modifications

Silos are defined as a metallic or concrete structure used for the storage of granulated materials. It is commonly part of a building which is, in turn, responsible for loading and/or unloading of the bulk.

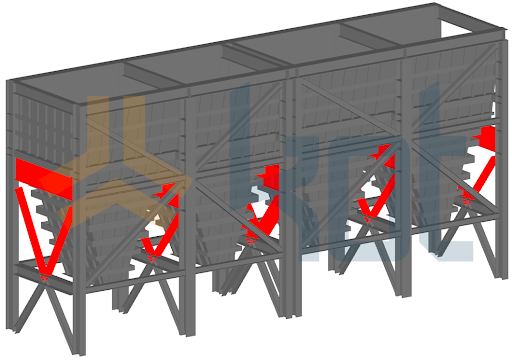

KOT carried out the structural evaluation of silos of an industrial plant and uncovered a problem in regards to the access to the silos during an operation due to the accumulation of materials. Thus, a set of potential solutions were proposed, amongst which the geometrical alterations of these assets in such a way that the material can be better spread. To ensure the applicability of the proposed alteration, KOT developed a follow-up structural analysis grounded on the Finite Elements Method.

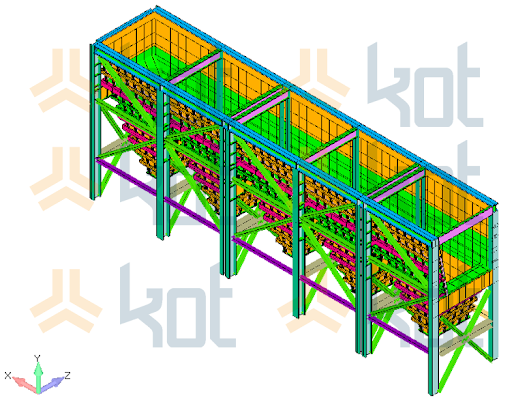

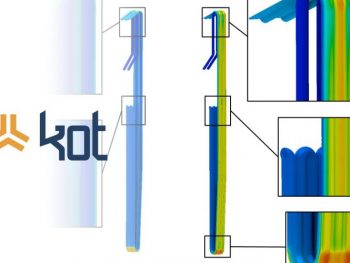

Initially the operation conditions for the potential alterations were analyzed, ensuring that the decrease in productivity would be the lowest possible. From that moment on, the structural alterations were implemented, reaching the model presented in Figure 1.

Then, the asset was submitted to different kinds of analysis, as can be seen in-depth below:

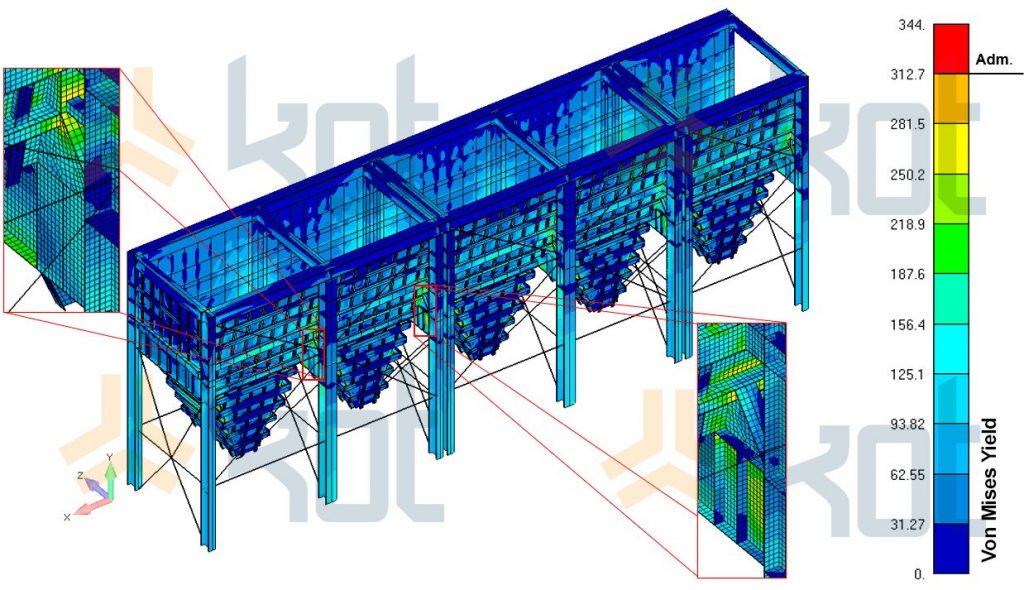

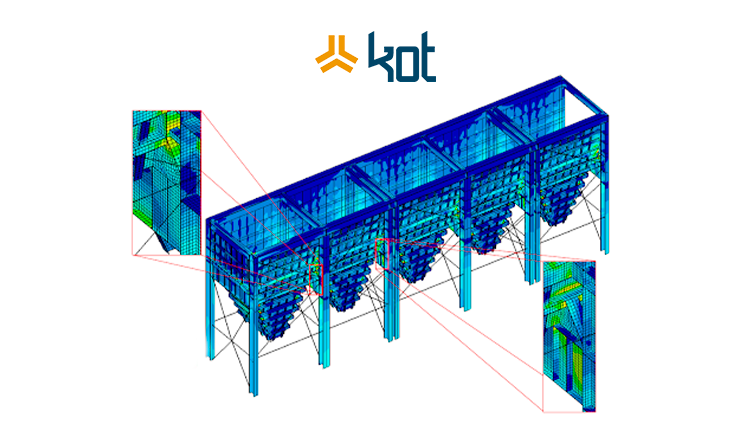

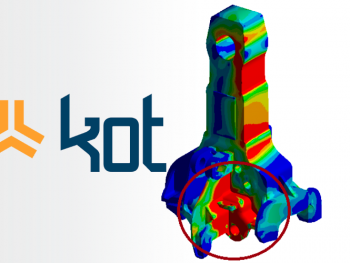

- Static Analysis:

It was used to make the first structural check of the new geometry. Here, the voltage acting on each element was indicated by means of a color scale, where the red reveals indexes above those permissible as a rule. At that time, it was noted the need to include reinforcements so that there were no stress concentrators located in the structure. The final result is shown in Figure 2, where the structure is approved.

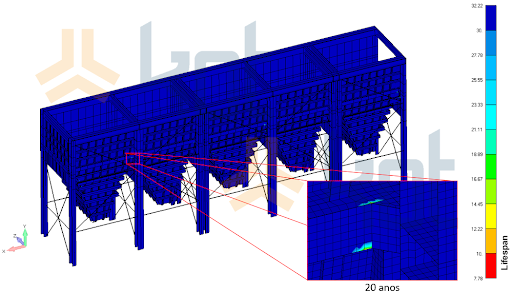

- Fatigue analysis:

This stage assessed the lifespan of the structure starting from the number of cycles of the operation, considering the profiles, plates and metal links of the silos. After the reinforcement, the most critical region, on figure 3, presented a 20 years lifespan, consistent with what was expected of the asset.

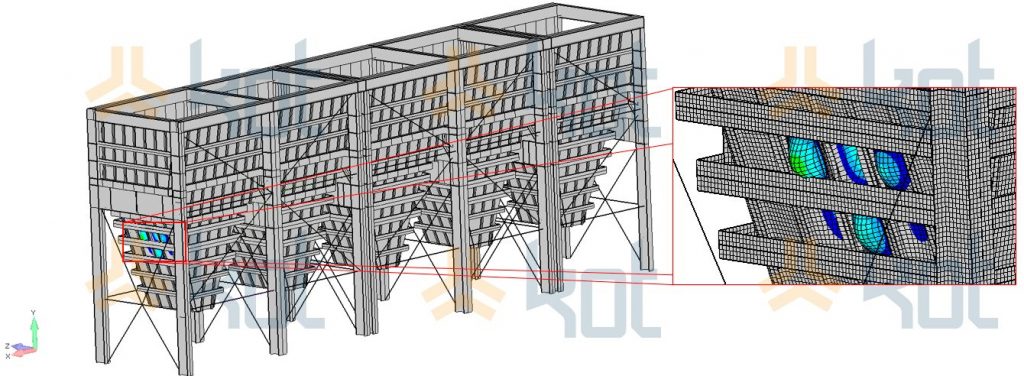

- Buckling Analysis:

The applied buckling analysis used a linear approach for the extraction of self-values from the stiffness system of the structure. The self-value consists in the ratio between the effort that would cause the element to buckle and the acting effort. Therefore, results greater than 1 indicate that the acting load is less than its buckling load. The entire system presented admissible values in the analysis.

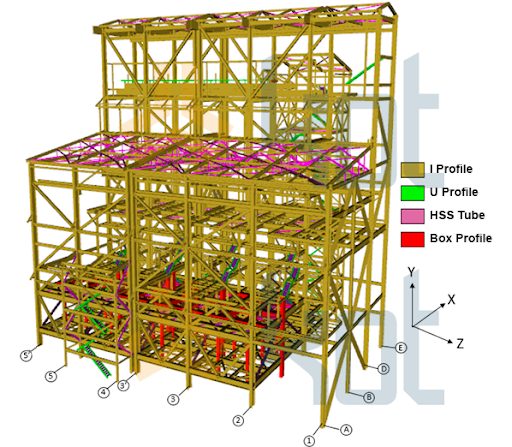

Considering the success on the silos alterations, the building to which it belongs was verified applying the new load conditions. The model in Finite Elements of column-beam is presented in Figure 5.

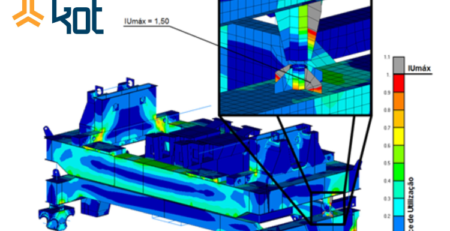

- Superstructure analysis:

The superstructure analysis includes the static verification and the metallic links. In that, the connections that should be changed in the support of the silos were indicated, including the installation processes and what inspections are the inspections necessary in this case. The changed connections are shown in Figure 6.

- Flexibility analysis:

The study also focused on the foundation connections, where the reinforcements were projected for the areas of nonconformity. Therefore, in the flexibility analysis, the displacements of the region of the main structure of the building affected by changes in the loading of the silos were verified, concluding that all values are lower than the permissible displacements. Thus, the modification of the silo has no impact on the compliance of the structure with its displacement service limit states.

- Civil analysis:

Finally, the infrastructure was analyzed. In the verification of the foundation reinforced concrete radius that supports the building pillars, the calculated soliciting efforts did not exceed the admissible ones. The soil also had sufficient resilient capacity to withstand the soliciting efforts.

With the study of this case it is evident that the importance of the structural verification after the suggested modifications for a specific asset. Such a decision is not exclusively applicable to the object being analyzed, but also to the overall combination which it composes. Carrying out installations and modifications before inspections, calculations and simulations can result in choices that only mask a non-conformity and, in the future, new problems may arise.

To further understand which solutions should be applied to your assets, get in touch with KOT Engenharia’s team.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] KOT Engenharia’s archives

Leave a Reply