Successful case: CFD analysis on floating pipelines

Introduction

In several scenarios in the industrial context, it is possible to observe interactions between a solid object and a flowing fluid. When the interest of study is the fluid that is flowing, it is possible to apply the technique of Computational Fluid Dynamics (CFD). If you are interested in this discipline, check the links below for some of the texts contained in KOT’s Blog about the subject:

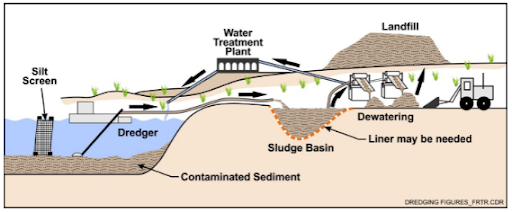

The Federal Remediation Technologies Roundtable, FRTR, defines the dredging process as the removal, treatment, and/or relocation of contaminated sediments or submerged contaminants [1]. This definition converges with the description of the environmental remediation dredging process described by the Brazilian Navy’s Board of Ports and Coasts, which states as “Act of removing material and sediments from the riverbed of water bodies, with specific purpose […] Performed for the improvement of environmental or sanitary conditions.” [2]. This modality of dredging is performed to reduce the risks of the materials to offer some kind of threat to human health or the environment.

The equipment used to perform dredging is known as dredges and is commonly classified as mechanical dredges, hydraulic dredges, or pneumatic dredges. It is also possible to find hybrid models of these machines. In short, their operation can be described as [1]:

- Mechanical dredges: equipment that perform dredging using mechanical devices, such as a clamshell

- Hydraulic dredges: equipment that perform dredging using the addition of water to form a fluid, with the material that will be removed, which can be pumped through pipelines

- Pneumatic dredges: equipment that perform dredging using pumping air to perform a suction of the material with a small amount of water

- Hybrid dredges: arrangement of equipment that use mechanical and hydraulic components to remove the material.

Figure 1 shows a schematic representation of the dredging, dewatering and water treatment process.

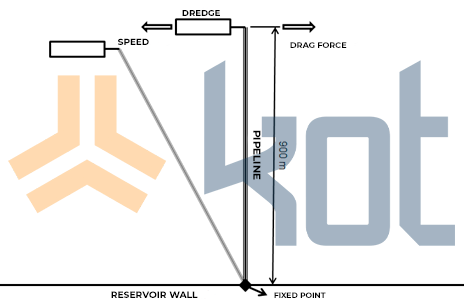

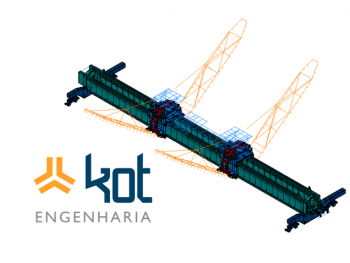

KOT prepared a study to analyze the drag on the floaters of the pipeline of a dredge. These dredges in question are responsible for removing tailings resulting from the bauxite ore washing process. These tailings are transported through a pipe to the reservoir wall. This pipe, in turn, is dragged by the dredge which, in contact with the fluid, generates a drag force contrary to the movement of the vessels.

Objective

The main objective of the study was to evaluate the drag force exerted by the movement of the dredges, in order to enable the definition of the technical specifications of the wire rope and anchoring bollards.

Development

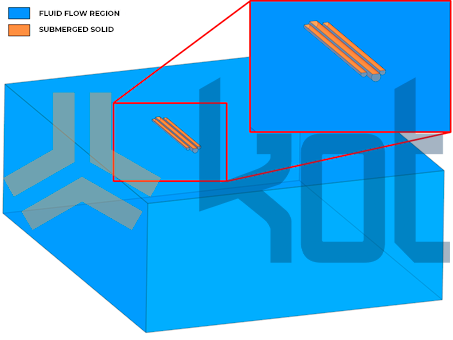

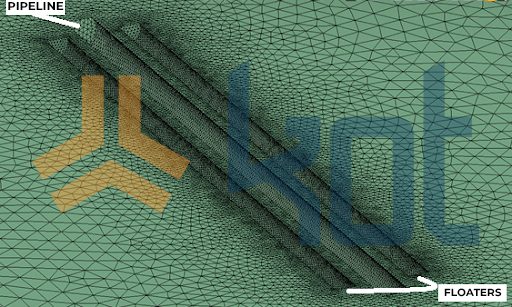

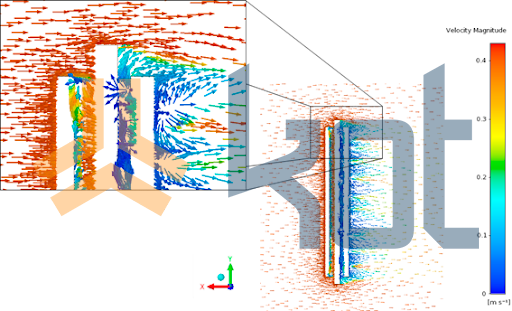

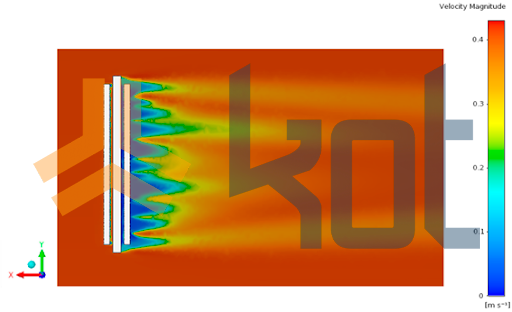

Starting the analysis, the model was created, and the boundary conditions – such as water flow perpendicularly to the pipe – were defined and used. Next, Figures 2 and 3 show the computational model generated for the study and the mesh used in the model, respectively.

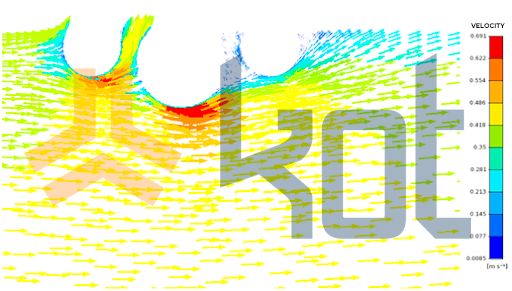

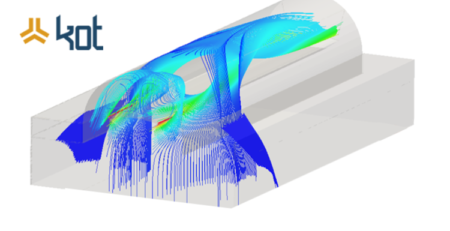

Some of the results obtained through the calculations and analysis can be seen in Figures 4 to 7.

Conclusion

The objective of the study was concluded with the help of the drag force equation. The computational analyses and analytical calculations for determining the maximum drag load acting on the pipes and dredges, showed that the drag coefficients are too high for the application, which influences the movement trajectory of the dredge, as presented in Figure 8.

CFD analyses have a wide range of application in the industrial context, not only in design conditions, but also to evaluate real scenarios of existing systems. These studies enable the physical-mathematical understanding of events that are complex and/or not visible to the naked eye.

KOT has experience in the area and can help you with your company’s needs. Consult our team of specialists to evaluate the possibilities of application in your context.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] https://frtr.gov/matrix/Environmental-Dredging/#Introduction

[2] NORMAS DA AUTORIDADE MARÍTIMA PARA OBRAS, DRAGAGENS, PESQUISA E LAVRA DE MINERAIS SOB, SOBRE E ÀS MARGENS DAS ÁGUAS JURISDICIONAIS BRASILEIRAS

[3] Acervo KOT

Leave a Reply