A success story: CFD-DEM analysis in a Bulk Transfer System

The Computer Fluid Dynamics analysis (CFD) is known for applying Finite Volumes Methods (FVM) to fluid flow problems, heat transference, amongst others, grounding itself on the concept of numerical and thermo fluid dynamic methods. Likewise, the Discrete Elements Method (DEM) is applied when the objective is to analyze the displacement and rotation of discrete bodies. In order to understand the differences between the methods, please read the article previously published on the blog. In this article, we introduce you to a case in which KOT Engenharia applied both concepts to the analyzes of an ore transferring system.

CFD-DEM analysis on an ore transfering system

A transfer chute is a component commonly found between conveyor belts used to direct the flow of material in the unloading process. A client company installed a new chute in its plant in order to reduce the generation and emission of dust to the outside environment. However, the new chute did not show such performance, and it is the scope of KOT’s work to identify the phenomena responsible for the generation and output of dust due to the transfer of ore to the environment.

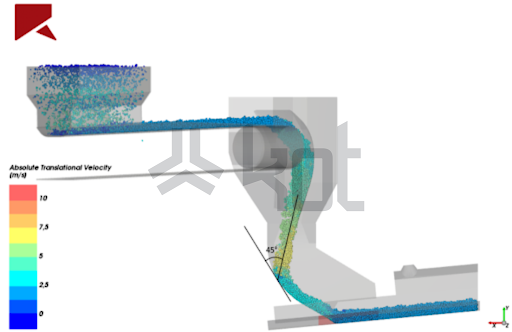

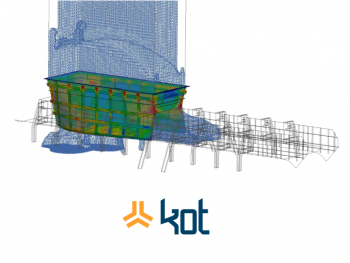

Initially the behavior of the bulk flow was analyzed through DEM on a specific software. The team was then able to conclude that there was no imminent risk of a clog, as can be seen on Figure 1.

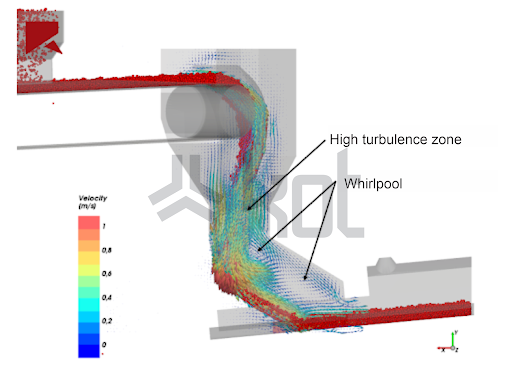

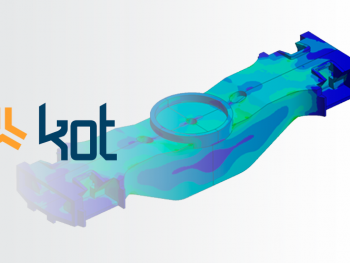

The same software was used for the linkage between CFD and DEM, aiming at evaluating the air flow inside the chute. Thus, it was possible to acknowledge the formation of whirlpools in the inside and in the high turbulence zone, which in turn increases the generation of dust. These results are presented on Figure 2.

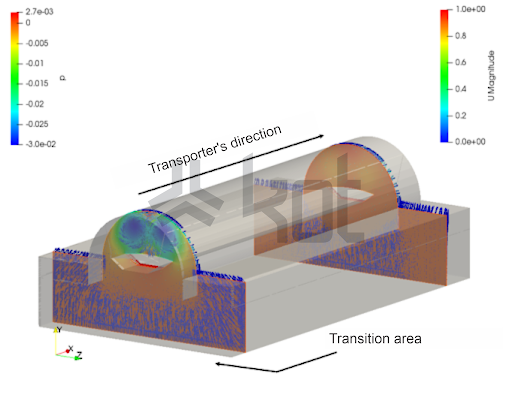

In order to further understand the observed phenomena, an air flow study took place on the material receiving transporter. Said transporter has its own system for the dust control, with a transition to the chain coverage, which carries out the same function. The analysis was accomplished using a computational fluid dynamic tool which is grounded on FVM.

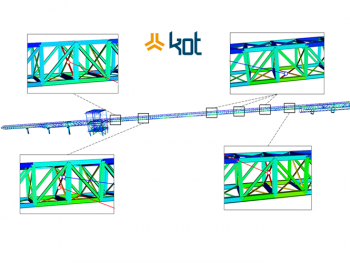

The team was then able to observe that the dust control system is well suited for its objective. However, in the transition region between the system and the conventional chain coverage, several factors favorable to the creation of dust were identified as there is no enclosurement. The formation of whirlpools can be seen on Figure 3. On the coverage exit you can also observe that the phenomena is softened.

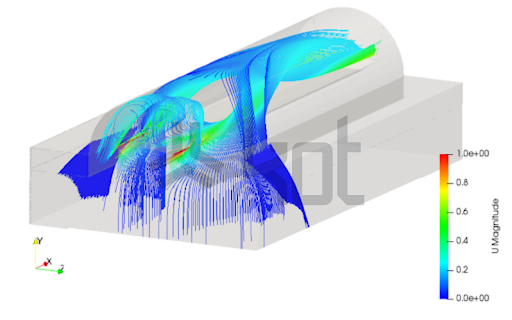

The turbulence regions along the covered area of the transporter were also analyzed, as can be seen on Figure 4, where the lines represent the air flow. There you can observe, once more, that the transition region is the most critical point in regards to the air currents.

Thus, the chute and the dust control transition region for the coverage are responsible for the elevated generation and release of dust. KOT Engenharia presented these problem causes and developed solutions, which involved geometrical alterations in order to adapt the flow and the methods to attain a better recirculation of air.

Get in touch with KOT’s specialists team!

Aender Ferreira

Mechanical Technician from CEFET-MG, Mechanical / Aeronautical Engineer from UFMG and Master in mechanical projects from the same university. Before graduation, he had experiences in the mining, maintenance, project design, experimental engineering and automotive industries. As an Engineer, he started his career in the maintenance sector performing calculus activities for fatigue in aeronautical components and structures. Subsequently, he was invited to compose the Board of Directors of KOT Engineering, working in the commercial sector of the company, helding the position for almost 15 years.

Leave a Reply