Vibration analysis using image processing: benefits and possibilities

Introduction

Inspections to monitor machinery and structures in manufacturing units enable the promotion of their structural integrity through the identification of anomalies and nonconformities. As previously discussed in the KOT Blog, vibrations can have harmful effects on industrial assets. Whether by resonance issues, reduced asset life or human discomfort.

The conventional method of using accelerometers enables, in several situations, the collection of vibration data on assets, but this methodology has limitations. This instrumentation is complex, especially in situations where the equipment or structure works in adverse environmental conditions. As the accelerometers must be fixed to the surfaces on which the vibrations are to be measured, factors such as high humidity, temperatures and viscosities can hinder and/or make it impossible to perform the study. Objects with badly corroded surfaces and high roughness can also impact the test.

This article discusses the advantages and applications of the innovative method used by KOT Engenharia to perform vibration analysis using image processing.

Methodology

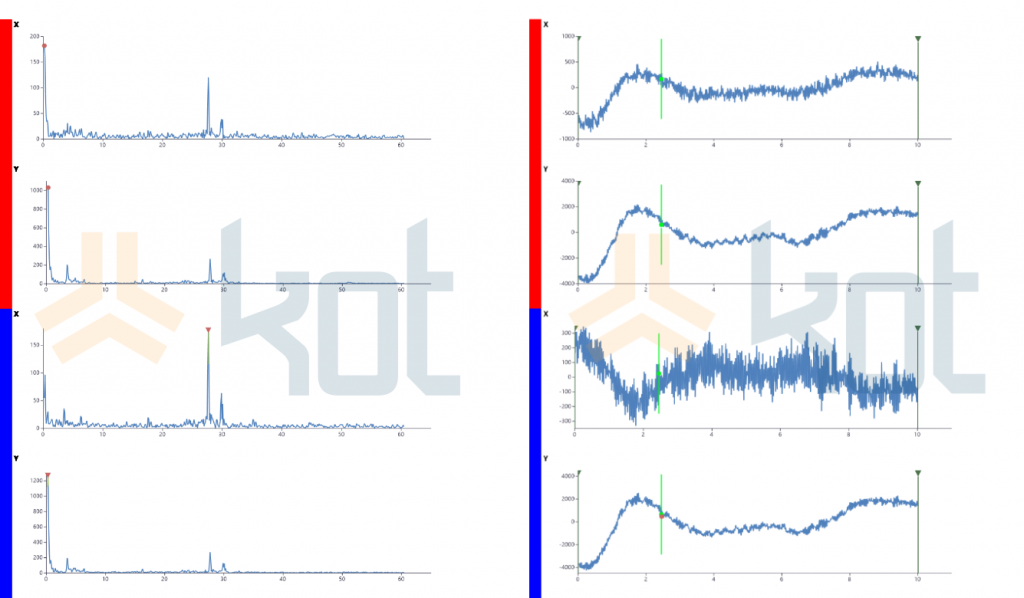

The system consisting of high-resolution and high-speed cameras, lenses, computers, and lighting systems is capable of taking measurements with micron sized precision. To do this, using the software in which the analysis is done, all the pixels of the image are mapped and can be transformed into “sensors”. After mapping, the points to be studied are defined and analyzed, and the vibration spectrum and waveform can be obtained.

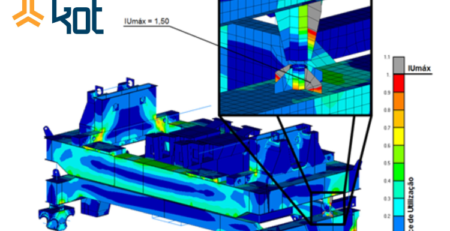

Figure 1 shows some results obtained by KOT’s team in a measurement on an engine and its base.

The generated data can be exported in a conventional format, enabling the insertion of the information in softwares for various analyses.

Benefits:

Some other benefits of using image processing for vibration analysis can be found below.

With a single collection, infinite analysis points can be generated without requiring multiple sensors, cables, and acquisition systems. The definition of these points must be strategic in order for the study to be assertive. The collection distances between the asset and the capture camera can vary from 30 centimeters to 20 meters, which expands the range of existing possibilities.

In addition, it can be said that data acquisition is faster when compared to the conventional method. Also, in comparison with the more usual methodology, one can notice a better performance of the image capture method against noise.

Industry Applications

Their applications in the industry are diverse and each scenario must be analyzed. However, some of the most common applications are listed below.

- Verification of road and railway bridges deflections;

- Orbit tracking of vibrating sieves;

- Vibration analysis in mechanical equipment foundations;

- Study of vibrations in industrial building structures;

- Vibration analysis in supporting structures of belt conveyors;

- Vibration analysis in silos;

- Vibration analysis in agitators;

- Vibration analysis in tanks;

- Detection of water hammer in pipelines;

- Automotive structure monitoring.

Video 1 shows the result of vibration analysis using image processing on a railroad sleeper.

Video 2 shows the result of another KOT job on an engine and its base.

Conclusion

The method offered by KOT is highly effective and can be used in several conditions and analysis. Furthermore, the company has qualified professionals to understand, execute and analyze its applications in industry challenges, helping to achieve goals and boost results.

Contact the team for more information and quotations!

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] Kot Engenharia’s archives.

Leave a Reply