The CARE Methodology

Background

Seeking to offer an Engineering solution aimed at promoting the care of its clients’ assets, KOT Engenharia developed CARE, a term from Portuguese which means – Asset Control for Structural Revitalization. As explicit in the name itself, the focus of this methodology is to care for the assets by promoting a structured control of them and mitigate the risks associated with the use of the equipment and structures.

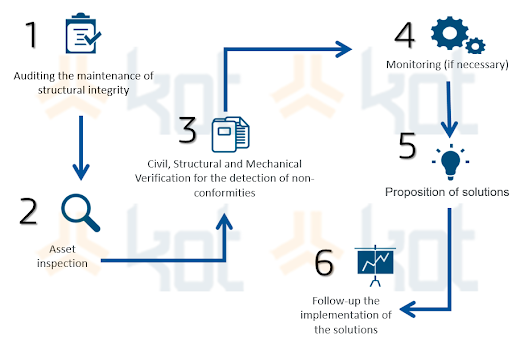

The methodology is divided into six main steps, establishing a journey that enables better maintenance and structural integrity of the asset. An overview of these steps can be seen in Figure 1:

Throughout its journey, CARE is based on risk management as advocated in ISO-31000 Risk Management, presented in Figure 2. It is important to emphasize that risk cannot be eliminated from human activity. However, the use of Engineering methodology in favor of its mitigation, can present benefits of reducing expenses, catastrophic failures, and saving lives.

Methodology Benefits

Based on the company’s experience over the years, KOT has observed that incorrect engineering practices entail an extremely high risk to the asset’s structural integrity and can cause serious accidents. In this sense, the CARE methodology presented herein comes precisely to go through the main stages of asset management, offering a series of benefits to its clients. From its implementation, the following advantages can be obtained:

- Safety:

An adequate project, a good state of conservation of the structures and their correct use are fundamental aspects for safety. Failures can generate production loss, injuries, or human losses, so the risk of structural failure is directly associated with the condition of the structures.

- Economic:

Besides the safety aspect cited above, there is a great economic benefit in the CARE methodology, since the investment values in the engineering of this type of solution are minimal compared to the eventual misfortunes that may occur. The following damages/costs can be avoided with the proposed solution:

- Losses of profit from downtime;

- Fines and demurrage due to delayed delivery of products;

- Urgent labor expenses for renovations, structure salvage, component/equipment replacement, equipment handling, etc. It is worth noting that these urgent costs are usually higher than the scheduled activities.

- Financial:

It is possible to generate advantages related to reducing the number of unscheduled downtimes. Thus, it is possible to achieve a higher level of productivity, which in turn is capable of generating a higher financial return on investment. Additionally, you can reduce OPEX due to the reduction of preventive and undesirable future corrective stops.

- Branding and Image Management:

One of the most precious assets a company has is associated with its brand and reputation among its stakeholders and society. The occurrence of accidents can culminate in irreparable damage to the corporate image, and it is difficult to evaluate this damage in financial terms due to its intangible character. Therefore, the concern with the sustainability and perpetuation of the organization goes through the concern and mitigation of potential business risks. The investment in preventive methodologies is a reinforcement to the ethical and sustainable positioning and the concern with its micro-environment (employees, environment and society).

CARE in practice

The CARE method in focus is in a very mature stage, being currently developed in different clients of the company, allowing a greater control in the Asset Management.

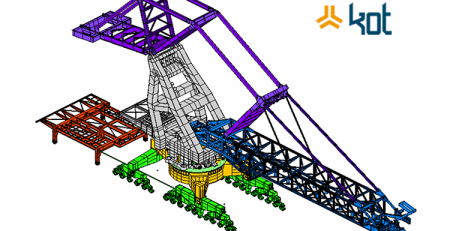

This service is applicable in plants of different sizes and processes that involve a series of structures and equipment such as belt conveyors, railcar dumpers, forklifts, reclaimers, transfer houses, buildings, among others.

The objective in its implementation is to guarantee the maintenance of structural integrity of the assets covered by CARE, acting in existing non-conformities, preventing possible occurrences of undesirable events, and prolonging the useful life in accordance with the best engineering practices.

For equipment to achieve the expected performance until the end of its useful life, it is necessary to identify relevant aspects that involve a series of events related to the asset’s life cycle, from its operation to its maintenance plan.

To illustrate what was explained above, we highlight here the main phases that make up the CARE methodology:

- Auditing the maintenance of structural integrity

Its objective is to audit the existing inspection processes, planning and execution of structural integrity, as well as related processes that influence the integrity condition of the assets, such as detective, sensitive and predictive inspection routines that contribute to the preservation and good operating conditions of these. The items verified by the audit consider the requirements of ISO 55.001 and good engineering practices, in the management and technical dimensions.

- Asset Inspection

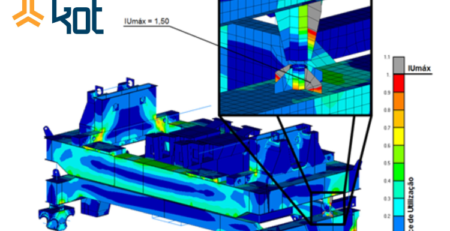

To verify the condition of the assets, one of the methods initially applied is to perform sensitive structural inspections. The verification can be done visually and with the aid of non-destructive testing (liquid penetrant, ultrasound and magnetic particle) to identify discontinuities that are not perceptible to the human eye as internal cracks and flaws in welds. If any deviation is classified as critical, emergency actions can be taken to act immediately and avoid structural collapse.

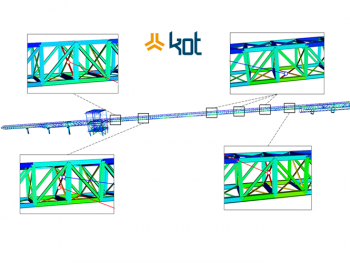

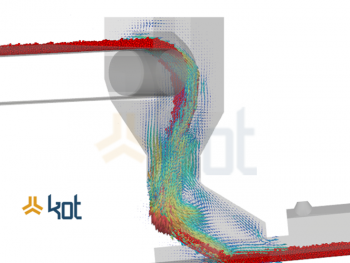

- Civil, structural, and mechanical verification

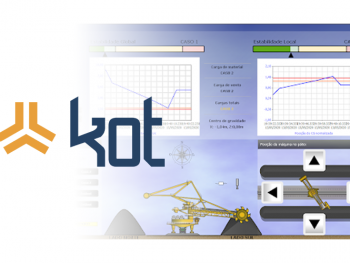

This is usually the longest step in the study, which involves the use of technical engineering knowledge associated with computational resources to elaborate verifications of metallic, civil, and mixed structures, and verification of the main mechanical components. Most cases involve computer simulation with the aid of Finite Element Methods (FEM).

- Monitoring

Eventually, it is necessary to do data acquisition in the field to verify the behavior of the structure in the operating condition to which it is subjected. For this, several techniques are used such as installing strain gauges to obtain stress/strain and monitoring the vibration condition, either by installing an accelerometer or by using image processing.

- Proposition of solutions

From the identification of non-conformities and their analysis, solutions are proposed aligned with the client’s needs. Alternatives may be discussed in terms of cost, efficiency, and implementation time to assist in the decision-making process. In general, drawings of reinforcements and/or modifications of the necessary adaptations for the maintenance of structural integrity are provided.

- Monitoring the implementation of the solutions

The correct installation of modifications or reinforcements is necessary for the structural integrity of the assets to occur, according to the recommended standards, and for risks to be mitigated. The case of incorrect practices at the moment of reinforcement, for example, is recurrent, which can represent a great structural risk. The main literature on the subject recommends that this service should be performed with the supervision and monitoring of structural specialists, thus avoiding the incorrect practices mentioned.

Ideally, the six steps presented here should be performed to increase the reliability of structural integrity. Possible deviations identified and solved by an efficient structural inspection, for example, may not be enough by itself if the maintenance planning is not adequate to monitor and act on the mapped critical points.

For several reasons, it is not always possible to act in all the fronts foreseen by the methodology. Thus, KOT seeks to understand the specific needs of each client and act in the appropriate steps for each reality.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

Leave a Reply