Project Auditing

Introduction

Within the engineering context, Project Auditing, also known as Design Review or Cross Check, consists on the verification of a wide spectrum of the project in different disciplines such as mechanical, civil or structural engineering. Which, in turn, can take place in diverse moments of a specific asset’s project cycle, being it new, being conceptualized or even currently at use.

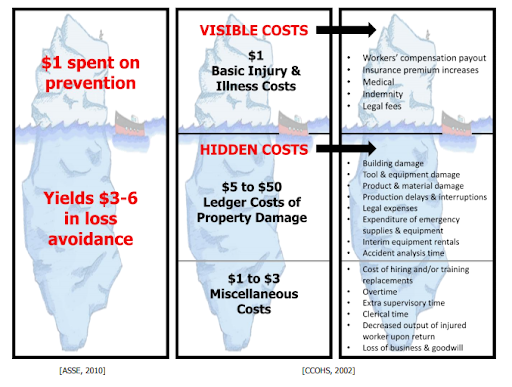

In situations involving large structures and equipment, the occurrence of defects can lead to large scale accidents involving human, environmental and economic impact. Financially speaking, a study carried out by the American Society of Safety Engineers [1] suggests that, for each dollar spent in prevention, three to six are saved in associated losses, as can be seen in Figure 1. Taking damage to property into account, that amount could amount to $50. Thus, the investment in project inspection has a significantly lower cost when considering the potential for hazardous consequences that a claim can have.

Phases of a Project Auditing

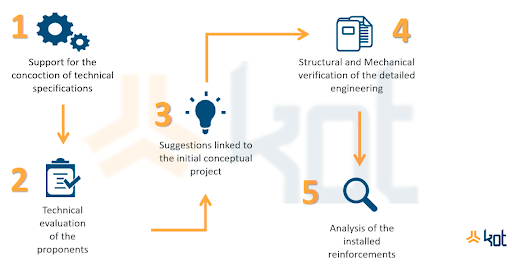

Auditing is a tool which complements the engineering daily services, identifying potential issues in the conceptualization of the project. In cases in which the service takes place considering the asset’s entire life cycle, there can be five distinct phases, as can be seen illustrated in Figure 2.

1 – Support for the concoction of technical specifications

This is the first stage of the auditing process, responsible for specifying the proponents and the design requirements as well as the standards that must be observed and the conditions foreseen throughout their useful life. A specification error in the incipient phase can compromise all other associated steps and generate serious losses.

Technical support also enables the client to unite all the engineering documentation which allows the verification of compliance with the requested items and eventual corrections of identified non-conformities. From the data generated in the process, a database is created that allows the incorporation of lessons learned into the company’s intellectual capital. In addition, it works as a customer protection mechanism against future demands or claims by competitors, as it allows the definition of premises for the execution of the contracting object.

2 – Technical evaluation of the proponents

After the elaboration of the technical specification, it is essential to evaluate the proponents critique, highlighting the companies which are capable to comply with the technical requirements requested. KOT is equipped to act as a technical support party for the client during the clarification meetings and the equalization of the proponents, allowing their technical advice at the end of the process.

Stages 1 and 2 are applicable, therefore, to the conception phase of the project and may provide the accident mitigation benefits and the best technical levelling between the process competitors. Additionally, as in the case of the technical specification, the customer can be protected from any inconvenience during the supply of the asset.

3 – Suggestions linked to the initial conceptual project

As a consequence of its experience, KOT may also act in the conceptual and initial phases of the project, verifying its adherence to the technical specification and pointing out any deviations identified. This phase’s objective continues being the client’s support with the technical assistance in the interface of the proponents, avoiding divergences in future, more advanced, phases of the project and consequently, impacts on the cost and deadlines due to potential re-work.

4 – Structural and Mechanical verification of the detailed engineering

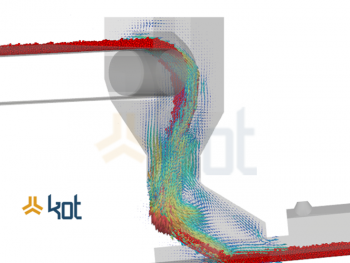

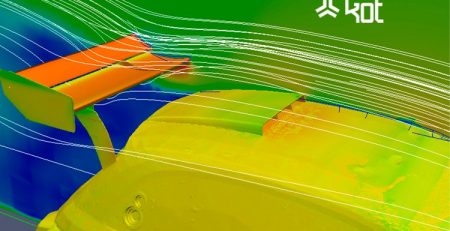

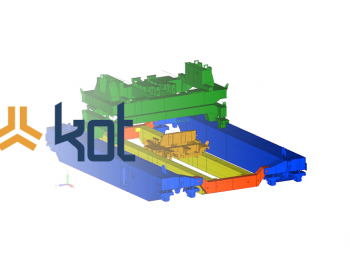

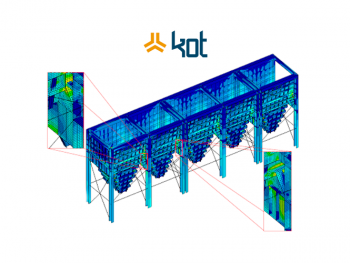

The most comprehensive stage of the study refers to the assessment of the complete technical documentation, contemplating production designs, material lists and equipment specification. Hereupon, computational analysis of the asset is carried out in a search for the identification of mechanical and structural non-conformities, generating suggestions for the optimization of the project.

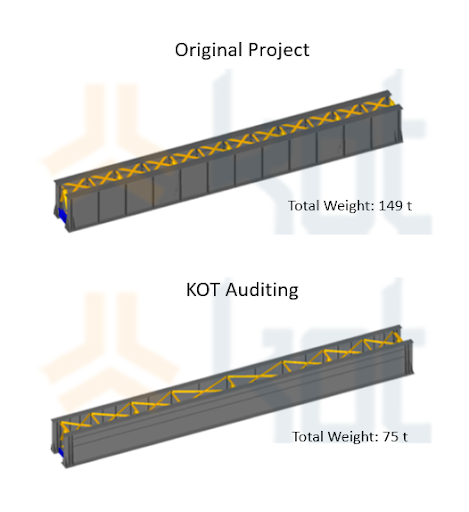

A recent study conducted by KOT involved verifying the detailed design of railway bridges formed by metal spans that were 25 to 35 meters long, for later manufacture in China. After assessing the due calculations for the verification of safety criterion, involving analysis like the pseudo-static of the steel structure, panel buckling analysis and fatigue analysis due to the train passing, design changes were indicated resulting in modifications of the stiffening geometry. The safety factors recommended by the standard were maintained and the weight of the bridge was reduced by approximately 50% in the case of the 35 meter span, as shown in Figure 3.

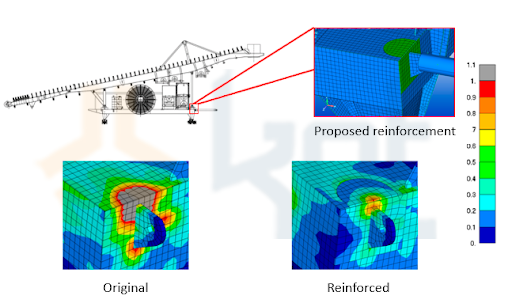

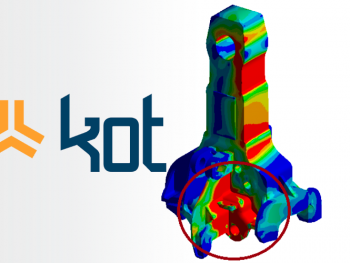

However, the most commonly observed fact in the project’s verification stage refers to cases of undersizing, that is, when the components do not have the strength or capacity to perform the function for which they were designed. In these cases, there is an addition of efforts or modifications at the conception stage of the project concerned about the structural and mechanical integrity of the asset. An example of this can be seen in Figure 4, which shows the region of the trailer where the reinforcement was proposed in order to reduce the rate of use of the structure, which exceeded the norm limit for the case of static analysis.

5 – Analysis of the installed reinforcements

Concluding the design review journey, the improvement recommendations proposed can be evaluated in loco, by duly trained structural engineers. There is a recurrence of incorrect practices associated with the installation of reinforcements, which compromises the previous steps, even if these are carried out according to the applicable technical criteria. In the event of deviations found in the field, solutions will be proposed to resolve non-conformities. On the other hand, if no divergence is identified, the asset will be adequate to the client’s requirements.

Conclusion

It is evident that countless benefits are generated by carrying out the project audit of structures and equipment and, when compared to the costs of a hypothetical accident, its cost is considerably lower. In addition to the financial issue, project non-conformities can generate even greater losses, involving lives and environmental problems, in addition to intangible aspects related to branding.

Ideally, the audit should be carried out as widely as possible to reduce the risks involved in the project as much as possible. Thus, the execution of the five steps presented gives a greater degree of protection to the client in the event of the occurrence of unwanted events. However, the limitations existing in each project may make it impossible to fully validate all stages and there is the possibility of partially contracting the audit.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References

[1] American Society of Safety Engineers. (2010). Reducing/Ignoring Workplace Safety Programs During Economic Downturn a Wrong Move for Business.

[2] MINE SAFETY AND HEALTH PROGRAM TECHNICAL STAFF (Colorado) (org.). Accidents – The Total Cost: a guide for estimating the total cost of accidents. Golden: Colorado School Of Mines, 2011. 29 p. Disponível em: https://www.mines.edu/emcis/wp-content/uploads/sites/185/2018/07/total-cost-of-accidents.pdf. Acesso em: 22 abr. 2021.

[3] KOT Engenharia’s Archives.

Leave a Reply