Successful Case: Stability Analysis

Used in stockyards for ore stockpiling, better known as stockyard machines, are large and important assets for mining companies. This equipment is responsible for handling materials in stockpile construction or reclaim operations. This article discusses the work done by the company in the stability analysis of an ore reclaimer.

KOT’s Blog has an expository text about the structural analysis of one of these machines and you can check it here.

Introduction

KOT took on the responsibility of analyzing a bucketwheel reclaimer. The equipment has been in operation since 2006 and handles iron ore with a high capacity. During operation, the machine is able to parallel travel to the piles of material and also slew around its own axis. The equipment has a boom capable of luffing vertically parallel to the height of the pile.

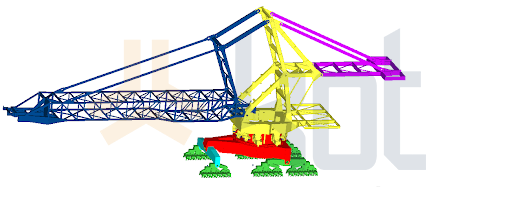

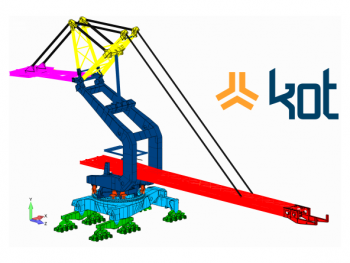

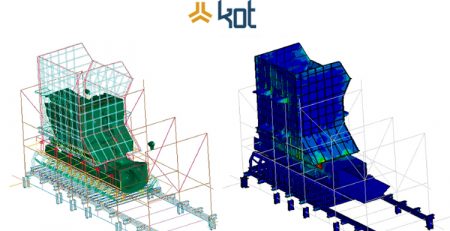

The computational analyses were performed using FEM software. The three-dimensional computational model of the reclaimer can be seen in Figure 1.

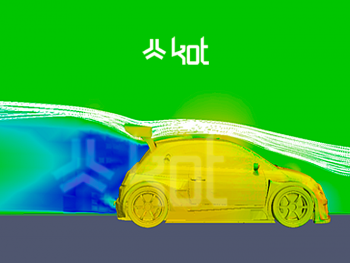

To begin the study, the first step taken was to model the reclaimer in finite elements. The machine structures composed of structural profiles were modeled in bar elements and statically verified according to the recommendations established in the standard. The other structures composed of structural plates were modeled in shell elements and evaluated according to international standard criteria. Some of the loads considered in the analysis are listed below.

- Self-weight of the steel structure and installed equipment;

- Material loading on belt conveyor;

- Dynamic effects of conveyed material;

- Overloading of stairs, walkways, platforms, and roofs;

- Wind loads;

- Chute clogging.

After modeling, application of loads and boundary conditions, the machine was evaluated from a structural point of view. More details of this analysis can be found in the successful case below.

Successful Case: Structural Analysis of an Ore Reclaimer Machine

Stability Analysis

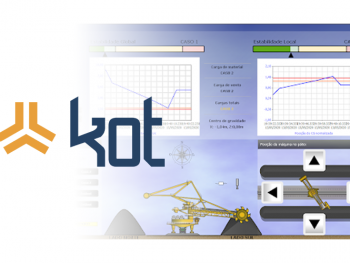

Global stability analysis consists of evaluating the possibility of a machine toppling over. To do this, the stability-related safety index, defined by standard, is calculated for all combinations of loads and operating situations relevant to the study.

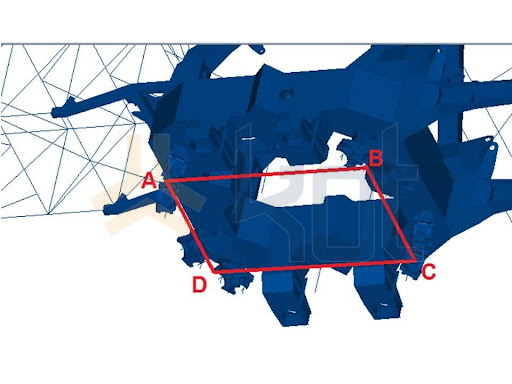

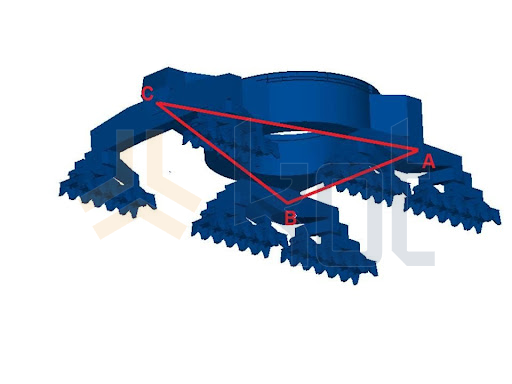

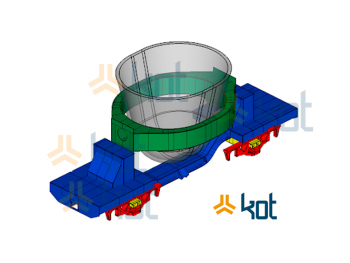

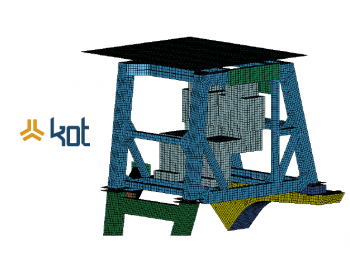

Two different stability studies were performed for the reclaimer, one considering only the slewing mass and the other with the complete machine. The first analysis checked whether there was a risk of the anti-topple over device being requested, while the second analyzed the risk of the complete machine topple over.

Figure 2 shows the stability polygon evaluated in the stability analysis of the upper part of the machine. Each edge of the polygon is considered a possible toppling over the axis that would trigger the anti-topple over device.

Figure 3 illustrates the stability polygon evaluated in the stability analysis of the complete machine. Note that each edge is also considered a possible axis of toppling of the reclaimer.

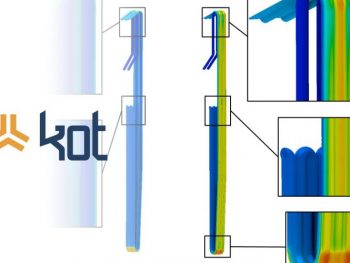

In order to validate the model created, KOT performed the instrumentation of strain gauges at points in the travelling system of the equipment. After installing the sensors, the operation commanded by the company’s team was performed, slewing the equipment in order to vary the demands on each leg of the portal to collect strain variations via extensometry.

The results obtained in both stability analyses were positive and the machine was approved from this point of view. It is noteworthy that during the analysis it was verified that the anti-topple over system would not be activated, and in both analyses all load indices found were lower than the safe one.

In addition, the data obtained through field instrumentation proved crucial to the validation of the study, because with this it was possible to determine the center of gravity of the equipment with the aid of the model generated in finite elements.

Conclusion

The stability analysis of stockyard machinery is an extremely important study for companies. Equipment toppling over can cause catastrophic accidents, leading to fatalities, production stoppages, and inestimable financial losses.

KOT has great interest and a wide range of expertise to study various engineering contexts. Contact the company’s specialists to understand how KOT Engenharia mayhelp you.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1]Kot Engenharia’s archives.

Comment (1)

I particularly appreciated the way you highlighted the importance of a comprehensive approach in analyzing stability and how it contributes to the success of the system. A thorough stability analysis can be a game-changer, preventing potential issues and ensuring smooth operations.