Successful Case: Conveyor Structural Evaluation – part 2

To perform analyses of machine structures, buildings, and conveyors through Finite Element Method (FEM), it is necessary that the professional in charge evaluate the normative criteria that relate to the problem and the behavior of the computational model. This procedure is important so that the evaluation to be performed by the professional represents the real behavior of the structure. Previously, one of KOT’s directors, Rafael Brasil, made a post on the company’s blog introducing FEM. A quick read may remind you of some important details about the method! Click here and check it out.

This text presents the report of one of the Engineers responsible for the Conveyor Structural Evaluation, described in the article: Successful Case: Conveyor Structural Evaluation – Part 1. Here will be presented the impacts that could have been generated in the result of a structural analysis if the boundary conditions were assumed wrongly. Find the shortcut to read the first part of the case here!

Introduction

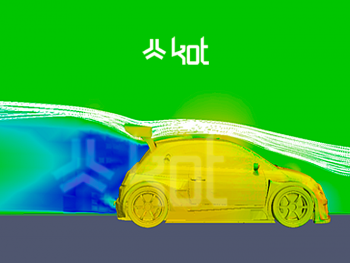

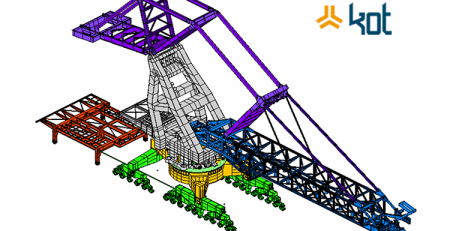

As presented in the initial conveyor analysis, this equipment is used for bulk material handling. It is carried out by a belt conveyor. Figure 1 shows an example of a belt conveyor.

The belt must be sufficiently tensioned to be able to handle any solid material. This stretching causes high magnitude stresses in the structures causing deviations in the belt’s direction.

Evaluated boundary condition

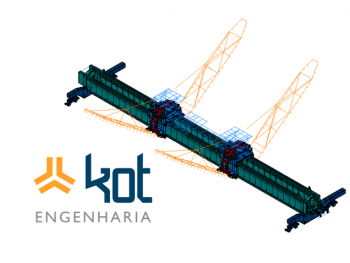

Upon starting the study, the KOT team soon noticed the first point of attention in the maritime terminal’s conveyor support devices.

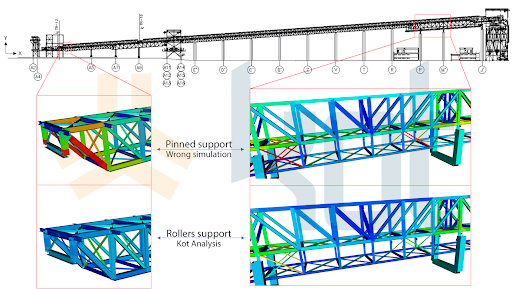

Pins are the most common linkage elements found in machines and structures. In this case, all it took was a little inattention to erroneously consider that the connection of this conveyor has pinned behavior, i.e., it restricts all degrees of freedom, except rotation about its Z-axis.

However, when the responsible team was studying the case, they realized that this device is composed of two rolls that allow translation in its X direction.

To better illustrate what a wrong analysis can cause, the comparative results for each of the above-mentioned boundary conditions are shown below.

Results

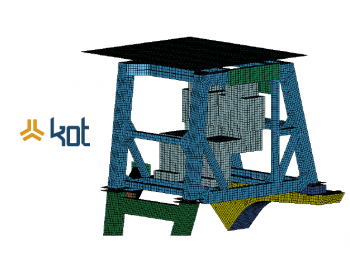

The wrong analysis of the support elements would have failed the structure because it would be considered that a pin-type device causes an increase in the stresses in the support regions of the conveyor, as shown in Figure 2.

Results discussion

It was found that the company that designed this structure was assertive in using a roller support. This is due to the fact that the adoption of the freedom of translation of the rollers, besides reducing the stress on the steel structure, also prevents shear forces in the longitudinal direction of the conveyor from being transmitted to the supports.

It is also commented that these roller devices are supported on isolated reinforced concrete columns that reach heights of almost 30 meters. Shear forces at the top of these columns, even if of low magnitude, would cause high bending moments at the bases of these columns.

In this sense, it is possible to conclude that the design decisions significantly reduced the cost of incorporating this equipment, when comparing the two analyzed situations.

However, from the perspective of the use of the structure, the project presents flaws, since the absence of horizontal restriction in practically all the trusses of the conveyor causes displacements of high magnitude, reaching 4.0 centimeters during the stretching of the belt and 6.7 centimeters in cases where the structure suffers setbacks due to temperature of around 20°C.

Animation 1 shows the longitudinal displacement of the conveyor during belt stretching.

Animation 2 presents the same situation on a reduced scale, showing some shrinkage rates of the structure in centimeters.

Conclusion

It was possible to observe that the wrong interpretation of the boundary conditions of a structure can influence the numerical results.

In this aspect, it is always important that the professional responsible for the analysis of a structure uses critical sense to interpret the data from a computational model.

KOT Engenharia has a team of qualified professionals with great know-how in the area of structural analysis, who are prepared to guarantee the structural integrity of our client’s buildings and machinery. Consult our team for further information.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] Abecom, (S.I). Available at: https://www.abecom.com.br/o-que-e-correia-transportadora/ – Accessed on 07/31/21 at 11:00 AM.

[2] Kot Engenharia’s archives.

Leave a Reply