Successful case: Railway Instrumentation

Kot executed an instrumentation project on a railway connecting two Brazilian states. In this article, you will learn more about how this successful case was developed by the company’s team!

Introduction

Derailments are considered to be extreme occurrences in railways which must be prevented as, besides causing material losses and service interruptions, they can lead to fatal accidents. In these cases, the main aspects to be observed are: the increase of the load on the wheel flange, the decrease of the vertical load, and the increase of the angle of attack of the wheels [1].

A method to evaluate derailing, proposed by Nadal, uses the lateral and vertical (L/V) loads. Once this coefficient surpasses Nadal’s limit, the wheel’s flange climbs and mounts on the rail culminating in the derailment [2].

Figure 1 presents the derailment mechanism in which Nadal’s conditions apply.

Computational model

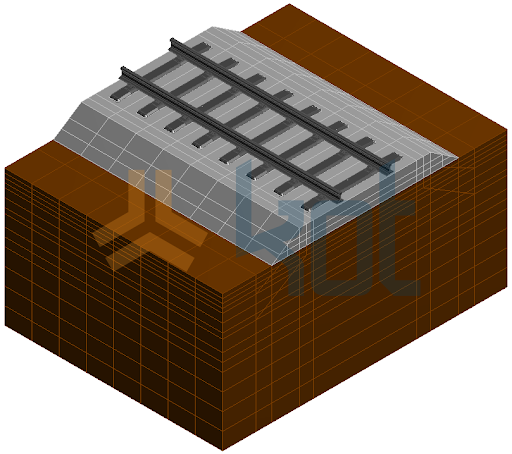

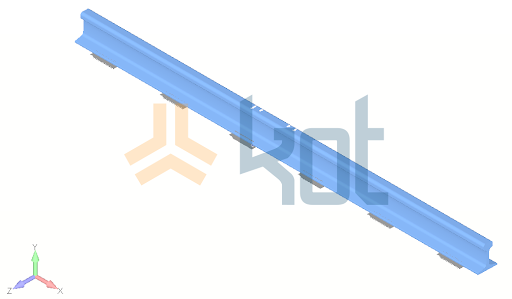

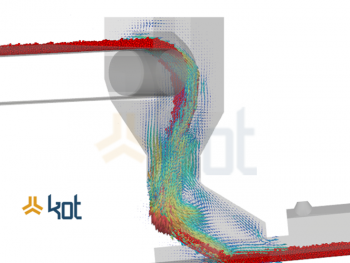

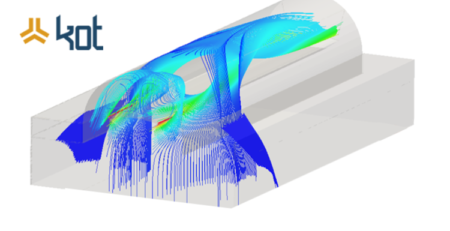

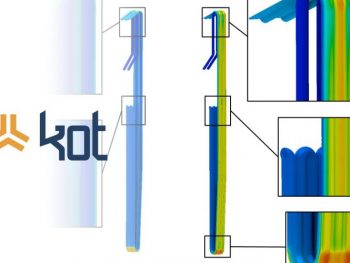

On a previous project, also performed by Kot, a railway was modeled, being composed by the rail itself, the sleepers and the track ballast, as portrayed on Figures 2 and 3.

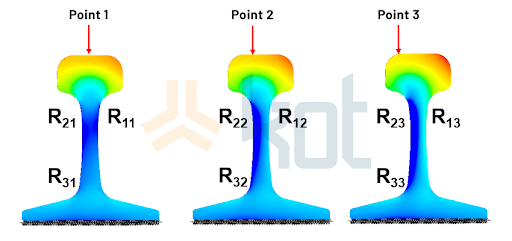

Vertical loads were applied to the model on to three different points of contact over and between the sleepers, assuming the eccentricity of the vertical load in relation to the centerline of the rail.

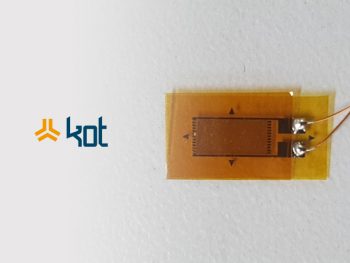

The Strain Gauges method used in this study is used for the evaluation of superficial material deformation. In order to understand more about the uses of the extensometer (also known as tensometer), you can read the following articles on KOT’s blog:

Kot’s instrumentation proposal

KOT’s proposed a methodology to perform the practical analysis as follows:

- In order to evaluate the vertical load, extensometers were installed on both sides of the rail’s web following the distances and alignment of the sleepers below. Thus, it was possible to properly collect the lateral and vertical loads. The calibration of the lateral load was done using a hydraulic cylinder. The following step was to analyze the influence of the vertical load over the lateral region, as can be seen on Figure 4.

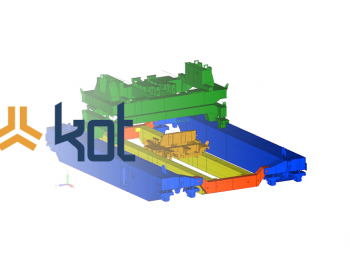

Strategic regions of the railway were instrumentation, chosen based on the history of previous failures. The measurements were done using strain gauges, both for the understanding of the deformations and the LVDT (Linear Variable Differential Transformer) and for the measurement of the vertical displacement of the sleeper for later analysis of the ballast’s stiffness. Images taken during the in loco period can be seen on Figures 5 to 7.

Main outcomes

The numeric results gathered were compared to those attained using computational simulations grounded on the Chevron Method. This analysis allowed the assessment of the eccentricity parameters effects on the vertical and lateral load values. Both methods presented the need for calibration for the due assessment of the deformations.

The advantages of the method proposed by KOT consists in enabling the acquisition of the essential data in cases of vandalism, cable breakage, among other errors. Furthermore, the presented methodology requires a shorter instrumentation period as it uses a smaller number of sensors than Chevron’s method.

Conclusion

The method proposed by KOT presents several advantages when compared with the conventional methodology as it favors the development of a study in a more reliable manner due to the analysis and comparison between the test data and the theoretical computational model. Moreover, the instrumentation is accomplished within a shorter period of time, which in turn renders the study even more interesting for other companies. It is important to also highlight that KOT has a long history of successful cases in the field, having performed several instrumentations of assets, being able to assess different operational contexts, and contributing to our client’s results. Get in touch with our team for further information!

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] GWALIOR, MAHARAJPUR, A Technical Guide on Derailments, CAMTECH/M/3, Abril 1998

[2] B. MARQUIS & R. GREIF, “Application of Nadal Limit in The Prediction Of Wheel Climb Derailment”, in Joint Rail Conference, [S.I], 2011.

[3] Kot Engenharia’s archives

Leave a Reply