Discrete Event Simulation

Core concepts

Computer Aided Engineering, also known as CAE [1], can easily be defined by the usage of computers in order to improve or assist engineering solutions or the development of products for a wide range of industries.

Within the statistical context, two main variables stand out: continuous and discrete. Learn, with this article, how CAE and the discrete variables are related and applied in engineering. First and foremost, it’s crucial to understand the difference between continuous and discrete variables.

One can even declare that continuous variables are infinited and that they are always somehow connected. Discrete variables, on the other hand, are countable and there are no elements between them [2]. To better understand this concept in a practical scenario, observe Figure 1.

In order for one to read an analog clock there are infinite possibilities,as it is not possible to fully grasp the exact location of the clock’s hands. It is also possible to observe that there are changes between glances. These characteristics define the analog clock as a continuous variable.

On the other hand, the digital clock only allows for one read at a time, therefore not enabling multiple reads in between glances. These facts thus, qualify the digital clock as a discrete variable.

Grounded on these variables principles are the continuous and discrete models. On the first, the state of the system is altered continuously according to the time, whilst on the second, the system is only changed when there are changes on the event.

The Queuing Theory

Overall, the Queuing Theory studies, through mathematical techniques, the objects flow through a network of processes. This chain reaction contains more than one location and some time and frequency restrictions for the passage of the objects [4]. These conditions generate the waiting times between the processing of the objects.

The main objective of the Queuing Theory is to create forecast mechanisms regarding how the lists’ system will behave [4]. Starting from this prognosis, assertive actions can be taken for the optimization of the processes and prevention of potential bottlenecks.

Industrial applications

In order to satisfy the industrial needs as a whole, Kot Engenharia grounds its propositions in concepts such as this, also focusing on other statistical and mathematical principles, aided by CAE methods to develop Discrete Events Simulations.

In other words, the Discrete Events Simulations emulate virtual lists scenarios. In these lists arrivals, procedures or services and exits of the objects can be evaluated according to the object being analyzed [5].

Advantages and Limitations of Discrete Events Simulations

First of all, it is possible to highlight that most of the real systems present a high level of complexity thus rendering it impossible for analytical evaluations. In these cases, the simulations can be used as a replacement. Besides, the virtual context of the simulation promotes other advantages such as the possibility of evaluating and comparing systems under specific conditions.

However, the main barrier which can be found for the discrete events simulation are the software elevated costs available for its execution.

Stages for Discrete Events Simulations [6]

- Model design: at this stage the system is analyzed with the objective of understanding its peculiarities, the objects of this simulation and the level of details intended. It is also in this phase that the needed data is collected;

- Model implementation: the second development stage contemplates the computational system modeling;

- Final model results analysis: final stage in which the model is ready and is used to attain more assertive conclusions and decisions.

Coal Port Analysis

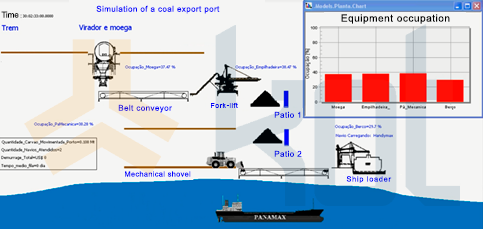

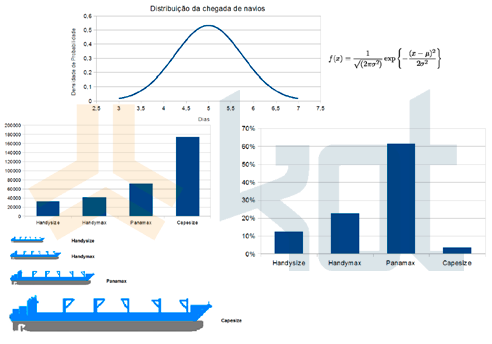

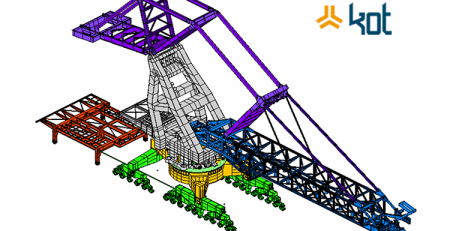

In order to facilitate the method application understanding, we will present a case in which Kot developed an analysis of Discrete Events at a port used to export coal. The study covered all stages of the process: from the arrival of the material from the railway logistics, through the transportation and stocking in the warehouses to, eventually, the recovery of materials, transport to the port and loading on to the ships.

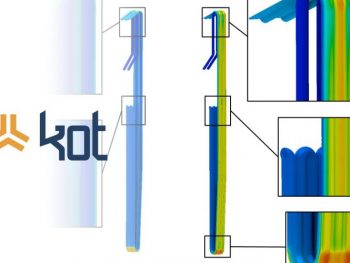

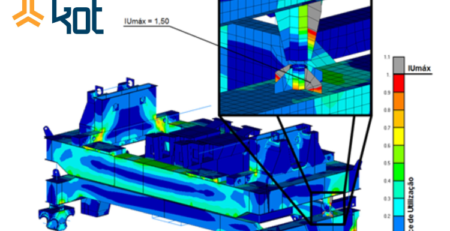

From the developed model, it was then possible to establish and quantify the occupancy level of the equipment in each phase of operations of the port (as can be seen on Figures 2 and 3).

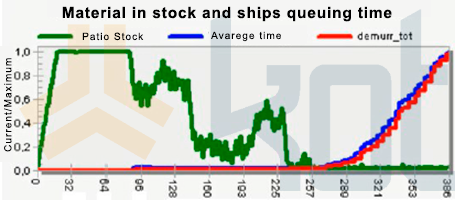

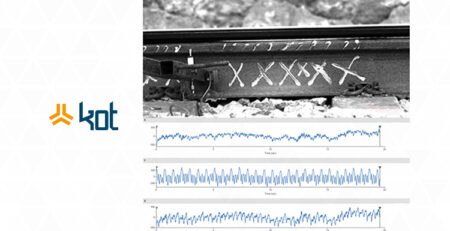

The results of a year’s operation, acquired before Kot’s intervention, can be seen on Figure 4.

Taking into consideration the simulation results, problems were detected in maintaining the port’s stocks. With that, Kot suggested some changes in the analyzed plant.

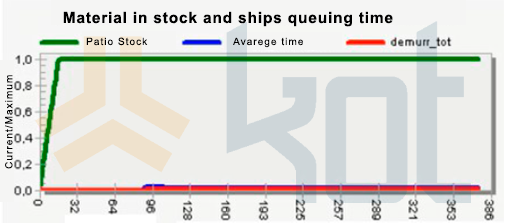

With the implementation of these alterations, a second simulation was carried out, corroborating the efficacy of the modifications and the adequacy of the port to the usage proposed in the project. In which case, there was no need for any additional investment in the plant, only adjustments to the processes. The new simulation, with the suggested changes applied, can be seen in Figure 5.

Conclusion

With mathematical and statistical knowledge combined to the CAE methods, Kot Engenharia is able to carry out a complete study of a process system, identifying potential bottleneck points and suggesting modifications for process optimization. Kot is able to evaluate different processes and operations to contribute with the results’ optimization. Consult our team for more information.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] B. Raphael and I.F.C Smith – Fundamentals of Computer Aided Engineering

[2] Miller, J. (1988). Discrete and continuous models of human information processing: Theoretical distinctions and empirical results.

[3] Kot Engenharia’s archives

[4] Newell, G.F.N – Applications of Queueing Theory

[5] Fishman, George S. – Discrete-Event Simulation: Modeling, Programming, and Analysis

[6] Chwif, L. and Medina, A. C. (2006). Modelagem e simulação de eventos discretos. Afonso C. Medina.

Leave a Reply