How computational techniques have changed the industry

As briefly discussed in the Successful Case: Railway Center Buffer Coupler Analysis article, Industry 4.0 has inherently brought several innovations to the industry in general and one of these innovations was digital simulations.

The objective of this article is to show how these computational techniques have changed the course of companies that deal with engineering.

The growing demand for cost reduction and optimization of assets, materials, and industrial processes daily encourages engineers around the world to analyze all stages of the production chain, from the initial steps of the conceptual project to the delivery of the product.

Today, the techniques and tools to perform these studies, in order to improve processes, can already be classified as mature and powerful and serve various markets, such as: aerospace, automotive, construction, mining, etc..

In addition, modern computers are increasingly capable of meeting the needs of these engineers to help them develop these activities. [1]

After all, how computer techniques have changed the industry?

There are several aspects to be analyzed when trying to answer this question, therefore, for the present text, two of these topics will be addressed: CAD and FEM.

Computational techniques have revolutionized practically all numerical and operational engineering activities. From the easier development of a project with the help of specific Computer Aided Design (CAD) software, or even for tasks that have a high level of complexity, such as structural calculations.

Computer-Aided Design

Computer-aided design techniques represent a true revolution compared to the old hand-drawn drawings. The productivity gains are enormous, because unlike drawings prepared manually in two dimensions, in a CAD environment it is possible to develop projects in three-dimensional models, easily editable.

This software optimizes tasks, making it possible for those who carry them out to act with greater agility and precision. This precision is directly related to the reduction of errors and the consequent increase in the reliability of a project’s execution.

The virtual CAD environment favors the visualization and understanding of the project, points that, in addition to providing greater speed in interpretations, reduce the chances of errors in the conception of the object to be built.

In addition, one of the best practices in engineering is the revision of a work by a different professional from the one who performed the activity. In such cases, it is normal to have indications of points for alterations and corrections, which are met much more simply and quickly when the drawing or project was executed with CAD.

Numerical Methods

Numerical methods are powerful tools for solving complex engineering problems, but in many situations, they require resolving overly extensive calculations, which makes solving them manually impractical.

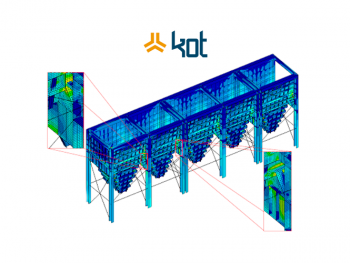

In this sense, for structural calculations, Finite Element Method (FEM) the finite element method (FEM) can be of great value. In short, with the aid of specific software, the structure to be analyzed is discretized into small elements, with the same characteristics of the original body, which can be more easily described by differential equations and solved by the mathematical model generated.

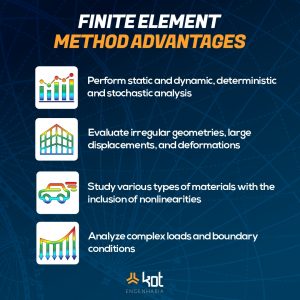

By dividing a complex problem into smaller problems that interact with each other, FEM makes it possible to evaluate irregular geometries, large displacements, and deformations.

The technique allows the calculation and application of complex loads and boundary conditions, and thus makes it possible to perform static, dynamic, deterministic, and stochastic analyses of a problem with computer simulations.

These and other advantages of FEM are shown in Figure 2.

Read more about the finite element method also in the article: Understanding the Finite Element Method (FEM). Understanding the Finite Elements Method (FEM.

In addition to FEM, there are other numerical methods that have also changed the engineering context during the fourth industrial revolution. Among these are DEM and CFD, methodologies that have already been extensively covered and discussed in Kot’s Blog. Read more about these topics in the texts:

- Discrete Element Method: what is it? Discrete Element Method: What is it?

- Computational Fluid Dynamics: the physics and mathematics involved in CFD analyses Computacional Fluid Dynamics: the required physics and maths behind CFD

Conclusion

Industry 4.0, although still in development and in the process of application, has already revolutionized a lot of industrial activities through computational techniques. Among these evolutions, those provided by CAD and FEM methods stand out, themes of high recurrence in Kot’s Blog.

The methodologies for using CAD and MEF are part of the legacy that professor Ihor Kotchergenko, Kot’s founder, left to the company and implemented at the Military Institute of Engineering (IME).

The company follows up on lessons taught by the professor and is able to assist you with your needs by assessing context and proposing solutions. Consult Kot’s team of experts for more information!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] RAO, Singiresu S. Engineering optimization: theory and practice. John Wiley & Sons, 2019.

[2] KOT Collection

Leave a Reply