Ubiquity of thermofluid-dynamic analyzes in industrial processes

Often, in industrial operations, it is possible to observe situations in which heat and mass exchanges might occur between two or more phases. These processes often multiphase permeate several sectors, such as: steel, automotive, food industry, aerospace and many others. Nowadays, it is impossible to ignore the benefits of understanding this phenomena and obtain the best outcome of the processes in favor of cost reduction and increase in productivity. In order to ensure a proper interpretation, some research areas were developed focusing on these processes, like for instance, the knowledge in thermodynamics, chemical kinetics, porous medium, heat and mechanical transfer of fluids. The domain of the concepts involved is needed for the development of projects and the optimization of complex industrial operations, thus providing the mandatory comprehension surrounding transport phenomena. The adequate use of disciplines is primordial so that processes involving heat and fluids can perform accordingly with the project, without production interruptions and incurrence to the products involved.

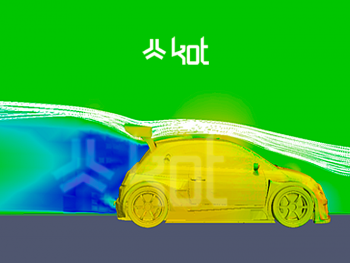

Besides the industrial applications, fluids such as water and air are essential for the average day and life on the planet. We can easily observe daily the effects of these engineering concepts when it is acknowledged, for instance: refrigeration of heat generating equipment and in food; the thermal comfort offered by air conditioning systems; the food processing in ovens; the effect of aerodynamics on the performance and consumption of vehicles and aircrafts.

What is thermofluid-dynamics?

Thermofluid-dynamics is the science field responsible for the development of theoretical and experimental research focused on the dynamic behavior of fluids and the phenomena associated with the transference of heat and the mass transportation.

Thermofluid-dynamics studies single and multiphase processes and can be directly associated to specific phenomena, i.e.: combustion and thermal radiation. Combustion is an exothermic and irreversible reaction which occurs between two or more reagents, requiring the presence of fuel and oxidizer. Thermal radiation, on the other hand, is identified by the emission and propagation of energy through electromagnetic waves.

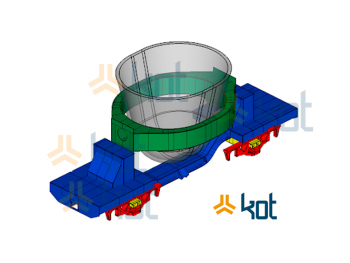

In industry, we have some equipment and/or structures which observe the heat and mass transferring between different phases phenomena, containing or not the presence of chemical reaction. Examples of such are: ovens, heaters, dryers, bag filters, capture and sedimentation channels.

In the last decades, the operational evolution of this equipment has been propelled by the development of numeric methods. The combination of thermofluid-dynamics studies with the application of said methods into multiphase simulation processes enabled the advancement of a very popular field of engineering: the computational fluid dynamics.

Computational Fluid Dynamics enables the creation of model for the analyzes and study through numerical simulations of fluid flows, heat transfer and other related phenomena.

Applications and benefits of Thermofluid-dynamics

Thermofluid-dynamics is largely used in different market fields and supports projects and the fabrication of hundreds of products. Its application expands into aircraft production, as well as cars, ships and several kinds of industrial equipment.

Between the main applications of fluid dynamics, the following stand out:

- The oil industry;

- The steel industry;

- The food industry;

- In mining;

- Testing of propulsion systems and power generation projects in general;

- Cooling equipment;

- Aerodynamic and aerothermodynamic analyzes of aerospace vehicles and land vehicles (trains, trucks, cars).

Thermofluid dynamics also contributes in environmental issues assisting in the planning and management of water resources (analyzes and simulation of the release of pollutants and contaminants) and in the studies of characterization of gas dispersion.

To learn more about the world of engineering check our blog with other articles in numerous subjects.

KOT stands out in the national market offering high technical level engineering services for big companies. Find more about what we can offer,

Get in touch with KOT’s specialists team!

Rafael Brasil

Mechanical / Aeronautical Engineer from UFMG and post-graduated in Structural Engineering from the same university. He had the opportunity to work at the European Aeronautic Defense and Space Company (EADS), in Germany. He is currently Development Director at KOT Engenharia, leading dozens of projects related to the Structural Integrity of assets and equipments.

Leave a Reply