Railway Measurement Systems

Introduction

Instrumentation is used on railways in order to develop physical quantities monitoring (acceleration, velocity, temperature, etc) involved in this complex operation process. The techniques used for the instrumentation enable the understanding and evaluation of dynamic effects caused in trains (wagons and locomotives) and on the railway. Monitoring data enables the acquisition of essential data for decision making.

According to Railway Workers National Association (ANTF), 493,8 million of tons were transported in 2019, an increase of 95% since the beginning of operations in 1997. Nowadays, over 95% of the ore arrive at Brazilian ports through railways. In the case of the modal, more than 45% of everything transported corresponds to agricultural solid bulk for export [1].

According to the facts stated, the railway growth can also lead to issues in regards to the operational structure and safety. One such example is fatigue of the rail and other components of the train due to the increased load for each axis, as well as train’s composition speed alterations. Another point to be highlighted, still related to the load and speed variations, is the risk of derailment. Combined, all of these issues can severely impact the operation’s cost.

Railway Instrumentation

The wagon instrumentation aims to identify the points and regions of the railway that generate damage. Knowing these regions enables punctual and assertive interventions to the management for the promotion of longer service time for both the vehicle and the railway itself. For the acquisition of quantities involved in the operation process, an onboard instrumentation system is required, which may contain measurement devices such as: accelerometers, strain gauges, pressure sensors, temperature sensors, displacement sensors, GPS, etc. The system is capable of acquiring data from the sensors, acknowledging the dynamics of the wagon; issue alarms and link them to your global position, which in turn is monitored by GPS (Figure 1).

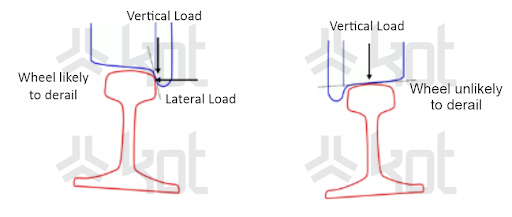

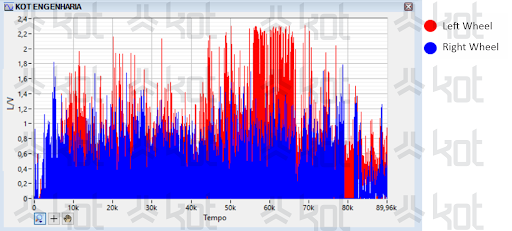

The measurement of deformation on wheelset, using the technique of extensometry for instance, makes it possible to indirectly know the lateral (L) and vertical (V) loads (Figure 2) that the composition is subjected along the railway. By measuring the load on the wheelset, it is possible to precisely quantify the peak load events during the journey. These events, which could lead to derailment, tend to be associated with significant changes to the track’s path (small radius curves), to the excessive speed of the wagons, or even to the events of sudden braking (emergency stops) of the trains. Figure 3 shows the derailment mechanism to which the condition defined by Nadal applies.

Also known as L and V loads of an operational path, the forces enable engineers to associate premature wear of components and reduce the risk of derailment events by determining the L/V coefficient. Figure 4 presents a graph constructed from data processing, measured in the field.

Railway instrumentation technique, carried out with the usage of sensors, studies and acknowledges of the physical measurements required for the correctly specification and use of sensors and data acquisition systems These parameters choices are associated with factors such as: what are the data expected by the requester, how many trips will be monitored, what is the duration and distance will be measured, what will be the format of the presentation to the client, among others.

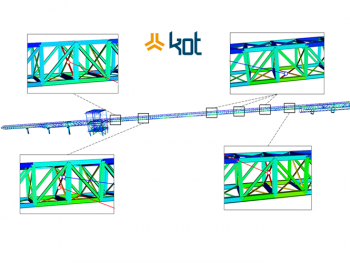

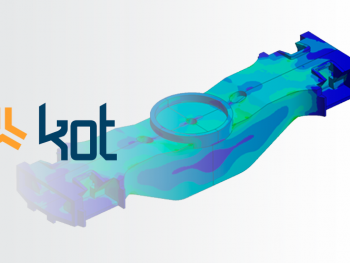

Besides the instrumentations done with sensors, other tools, such as cameras, can be used, as can be seen in detail on the article about Vibration analysis using image treatment, and emissions from alarms provided by the requester can be used and analysed using deformation data applied in studies using the Finite Elements Method (FEM). This study will enable the elaboration of fatigue analysis of components (shock and traction devices, bogies and wheelsets, for example), with the main target of estimating the service life in cycles for the client’s operational conditions determined and previously known.

Get in touch with KOT’s specialists team!

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

References:

[1] Associação Nacional dos Transportadores Ferroviários – ANTF. Disponível em: <https://www.antf.org.br/informacoes-gerais/>

[2] KOT Engenharia’s Archives.

[3] DALLY J. W., Experimental stress analysis, McGRAW-HILL, 3rd ed., 1991.

[4] AAR, Manual of standards and recommended practices. Design, fabrication and construction of freight cars, section C part II, 2011.

Leave a Reply