Belt Conveyor Pulleys: What are they and its importance

Introduction

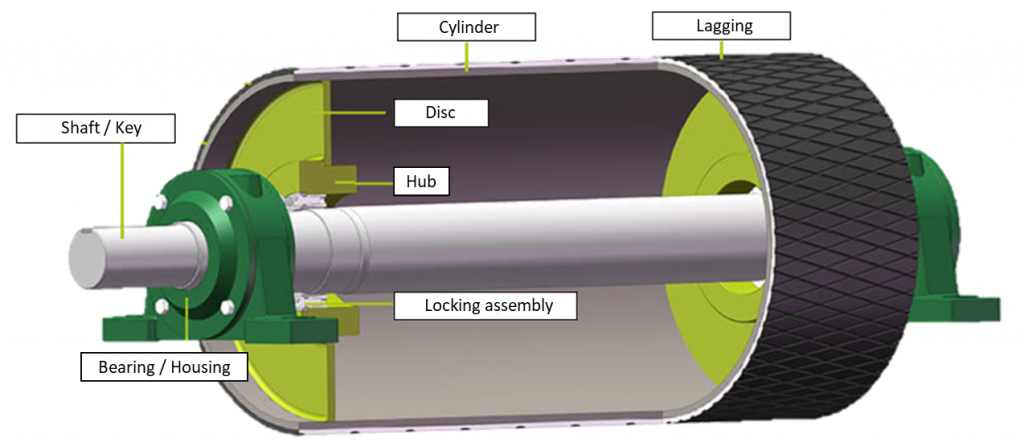

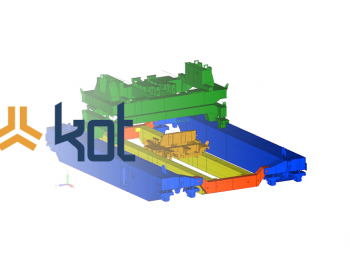

Pulleys are rotary components, used in belt conveyors, which have the function of transmitting movement, diverting direction or even stretching the belt. This equipment consists of four main structural components: the shaft, the hub, the disc and the cylinder. It is possible to visualize below, in Figure 1, the distribution of these elements in a drum pulley.

The pulleys are also composed of the expansion rings, which are commonly used to couple the shaft to the hub, and of the housings and bearings, which will be responsible for allowing the pulleys to rotate. For this reason, initially the bearing is selected and, based on its definition, the housing is selected, since each bearing requires a specific housing. Bearings and housings are selected based on minimum fatigue life requirements and bearing support load limits.

Pulley types

The pulleys have different functions on a belt conveyor, according to the position in which they are placed, such as providing deviations and folds on the belt. Hence, we can define some of the classifications for the component:

- Return: located at the opposite end to the discharge terminal, it has the function of returning the belt to its initial position, in addition to being able to also act in belt tensioning;

- Stretcher (take-up pulley): responsible for maintaining the ideal tension for the proper functioning of the conveyor;

- Drive: responsible for transmitting torque. This type of pulley can be located at the discharge, center or return of the conveyor;

- Deviation: has the function of diverting the course of the belt; 5. Snub: has the function of increasing the belt-embracing angle with the drive drum pulley.

Project and applications

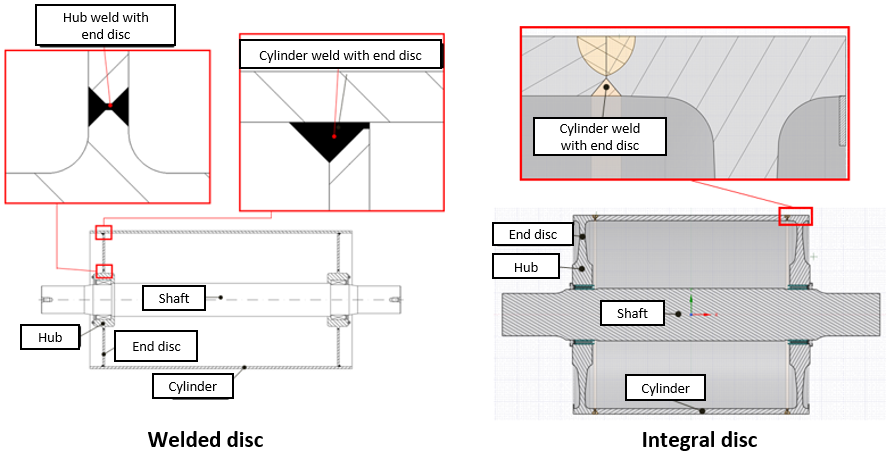

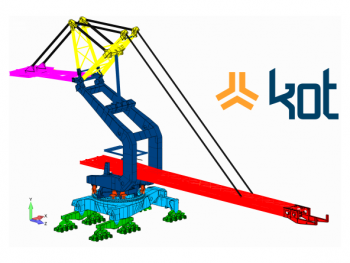

To dimension this type of equipment, the most relevant information is the width and tensions of the belt, in addition to the construction type. As shown in Figure 2, the discs can be manufactured integrally and connected to the cylinder by welding or they can be constructed welded to the hub and the cylinder. The pulley must be sized taking into account the positions and types of welding, in addition to the acting stresses in each of them.

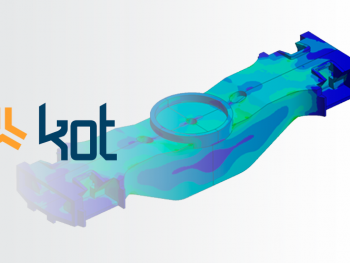

These equipment are usually made of steel and, as already mentioned, one of their main functions is to pull the belt so that the expected operation of the conveyor is achieved. In this case, the pulley to be used is the drive pulley, which is coupled to the drive unit, composed of motors and reducers. In some cases where it is necessary, a brake disc can also be coupled to the pulley shaft to be used with a conveyor braking system.

For operations where high belt tensions are required, different drive configurations can be used. Among them, the use of a drive set on more than one pulley can be considered, as well as the use of double drive on the same pulley.

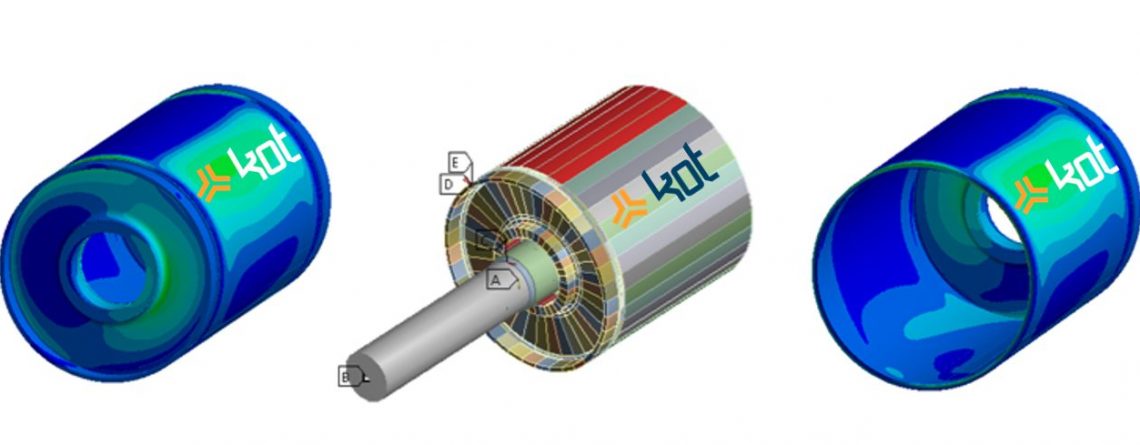

In Figure 3, it is possible to visualize the braking system on a belt conveyor, in addition to a pulley with double drive.

Due to the various applications of this equipment in belt conveyors, which use varied loads, its design calculation and dimensioning is done according to the load capacity of each conveyor. Its manufacturing also follows the technical standards applicable to this type of equipment.

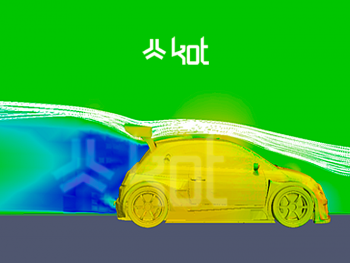

Another essential component in the use of pulleys is the lagging, which aims to protect the equipment against wear and also increase its traction capacity. Taking design variations into account, many factors must be considered when choosing a pulley for your belt conveyor, such as the cost of the equipment, the environment in which it will be installed and the ease and cost of maintenance. In addition to it, of course, the parameters for using the belt conveyor, such as tension, wrap angle, number of start and stop cycles and belt speed must also be analyzed. Figure 4 shows some lagging models, which will be selected according to the purpose of their use.

Market advantages

With the unceasing market growth, new opportunities arise for design and applicability of this component in environments that increasingly require greater capacity, efficiency or even safety. This results in a continuous development of technologies, with new lagging, dimensions and geometries, even more specific according to the needs of their application.

One of the main advantages of using pulleys is to transport materials over long distances, as the application of conveyor belts provides a significant cost reduction. This is achieved by reducing the number of trucks used to transport material, widely reducing the total work to be performed. In addition, it is also possible to reduce the direct interaction of employees with the material transport process and with the material itself, which provides greater operational safety. Another benefit obtained with the application of belt conveyors is a better control of particulate matter emissions. Some of the methods applied to conveyor belts for this purpose are presented below:

- Enclosure of conveyor belts: prevent the dragging of dust during material transfers;

- Application of dust suppressant: this product forms a film around the material, reducing dust emissions;

- Dedusting system: responsible for filtering the air before releasing particles into the atmosphere;

Another relevant factor is the conformity of the pulleys with the conveyors on which they will be implemented. It is essential to check the compatibility between pulleys and belts, avoiding later adjustments in the initial project or even rework to adapt components.

Conclusion

Pulleys are rotary components that are subjected to high cycling and high loads, resulting from belt tensions. It should be added that welding processes are inherent to the construction of this equipment, as it is also known that such processes favors the emergence of regions where crack nucleation is favored. For this reason, it is essential that the design of pulleys has high reliability, taking into account the correct manufacturing and sizing procedures based on the applicable standards, thus avoiding failures due to fatigue of both its structure and its components, increasing its rating life and equipment productivity.

After these considerations, the relevance of pulleys for the use of belt conveyors is evident. Special attention is needed in the maintenance and management of these components, avoiding production interruptions and always focusing on operational efficiency and safety. The drum set encompasses different parts, so that failures in individual components such as the bearing or expansion ring can compromise the entire functioning of the system. Therefore, carrying out inspections and structural assessments ensure greater equipment reliability, providing greater productivity and predictability for the maintenance of these assets.

Kot Engenharia has extensive experience in services involving pulleys and belt conveyors, performing everything from finite element analysis to pulley failure analysis, in addition to proposing project improvements. If you have needs for inspections and structural solutions, we have a specialized workforce to assist your business. Get in touch with our team!

References

- THE FUNCTION AND MECHANISM OF CONVEYOR PULLEY DRUMS – Terry J King Pr. Eng.

- Manual de Transportadores Contínuos Faço, Ed. Faço, 1996.

- Manual CEMA (Conveying Equipment Manufacturers Association), versão 93.

- Conveying Machines, Spivakovisky e Diaachkov, Editorial Mir, 1989.

- Transporte y Elevacion, P. Alexandrov, Ed. Mir, 1994.

KOT Engenharia’s Team

With over 29 years of history and various services provided with excellence in the international market, the company promotes the integrity of its clients’ assets and collaborates in solutions to engineering challenges. For this integrity, it uses tools for calculation, inspection, instrumentation and monitoring of structures and equipment.

Leave a Reply