Introduction

We know that projects are customized, but quality must be standardized. That said, how do you ensure that particularities don't affect the quality of the final object?

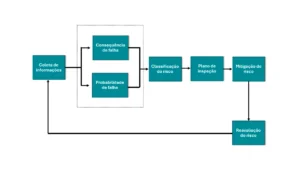

The answer to this question lies in due diligence. This service consists of specialized technical supervision, the aim of which is to ensure that a project is carried out in accordance with the technical requirements and regulatory standards required, within the client's specific needs. Due diligence encompasses a set of actions that provide the project with the quality standards required for safe construction and operation, as well as adequate planning that generates productivity and on-time deliveries. Figure 1 shows a typical flowchart for ensuring the quality of a project through due diligence.

Figure 1: Flowchart of due diligence steps.

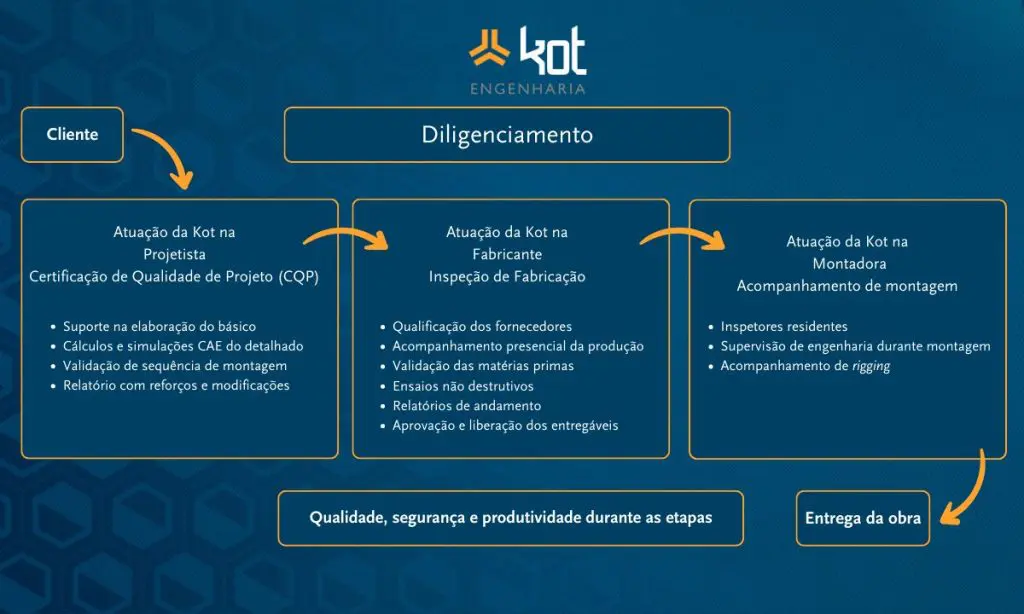

Major projects with large investments require detailed planning. Due diligence can also be a tool used to control the progress of the planning stages, through Project Quality Certification (PQC), manufacturer certification, manufacturing inspection and assembly execution monitoring.

How does Kot work in due diligence?

Kot's work in due diligence can take place from the start of the project right through to final delivery. Some of these services are discussed below.

Due diligence at project stage

Basic engineering and project certification:

Due diligence begins in the basic engineering phase, when the fundamental concepts of the project are defined. At this stage, engineers carry out preliminary analyses to determine the technical feasibility of the project. It is crucial to understand the project's requirements and constraints, identifying performance objectives and safety criteria. During this stage, technical specifications, material compatibility, expected loads and other essential variables are assessed. This stage involves reviewing every aspect to ensure that the basic design is sound and well-founded.

Quality certification plays a key role in any sector, ensuring that products, processes and services meet predefined standards and fulfill specific requirements. In the field of mechanical and civil engineering, quality certification of projects is essential to guarantee the safety, efficiency and functionality of mechanical structures and systems.

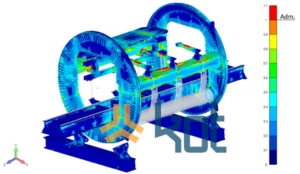

Audit by computer simulations:

A valuable tool in project management is computer simulation. It makes it possible to analyze the structural behavior of the project under different conditions, simulate extreme loads, test different operating scenarios and identify points for improvement. For example, in structural projects, simulations using the finite element method can reveal areas with stress concentrations, excessive vibrations, unacceptable deformations, etc. Auditing using computational methods makes it possible to detect problems early, before actual construction, saving time, resources and mitigating risks.

Evaluation of the assembly sequence and proposal of improvements and reinforcements:

One aspect that is often overlooked is the assessment of the assembly sequence. The way in which components are assembled and connected can influence the stability and safety of the structure. In project due diligence, evaluating the assembly sequence makes it possible to anticipate potential difficulties or risks associated with the construction. In addition, opportunities for improvement can arise during this process. Using the knowledge accumulated during assembly analysis, engineers can propose design changes to facilitate construction, reduce costs or increase efficiency. Standards also stipulate that the combinations and loads on a structure must be verified during construction.

Due diligence in the manufacturing phase

Supplier qualification:

Supplier qualification is an essential step in project due diligence, as it ensures that the company responsible for manufacturing has the necessary technical capacity and resources to meet the project's requirements. This involves carefully evaluating the supplier's experience, production capacity, quality systems, delivery history and compliance with applicable industry standards. Selecting unsuitable suppliers can result in delays, low-quality products and even safety risks.

Raw material validation:

Raw material validation is another critical stage in the manufacturing phase. Quality materials are essential for the integrity and durability of the structure. At this stage, suitable storage locations and methods are checked, and tests and analyses are carried out to verify that the materials supplied meet the required technical specifications and standards. This includes tests on chemical composition, mechanical properties and micro-structural analysis. Raw material validation is essential to avoid premature failures due to unsuitable materials, from the primary structure to the specific coating type.

On-site monitoring of production with Non-Destructive Testing (NDT):

O acompanhamento presencial da produção é uma etapa em que os engenheiros e/ou inspetores estão inseridos no local de fabricação para monitorar de perto o processo. Essa presença física permite uma avaliação em tempo real das operações, identificando possíveis desvios e problemas que possam surgir durante a produção. Além disso, os ensaios não destrutivos (END) são utilizados para verificar a qualidade dos produtos sem danificá-los. Isso inclui técnicas como ultrassom, partículas magnéticas e líquidos penetrantes, para metálicos, e ultrassom, tomografia, pacometria e GPR para estruturas de concreto. Os ENDs ajudam a detectar defeitos internos ou superficiais, atestando que os produtos estejam isentos de imperfeições que possam comprometer sua integridade estrutural.

Diligence in the assembly phase

In the assembly phase, where the project takes physical form, due diligence plays an indispensable role in ensuring that construction takes place accurately and safely.

Engineering support during assembly:

Engineering support is a central element in the process of setting up mechanical and civil projects. It involves providing technical guidance and assistance to the professionals involved in the construction. This can include the creation of detailed assembly manuals, component positioning diagrams, welding instructions and more. Engineering support validates that assembly is carried out in accordance with project specifications and established quality standards. It also helps to avoid errors that could lead to rework, delays, additional costs or even accidents.

Monitoring assembly and lifting:

Assembly monitoring is an activity that involves the presence of engineers, inspectors or specialized professionals on the construction site. The aim is to ensure that assembly is carried out properly, safely and in accordance with the project. During this phase, visual checks are made, possibly dimensional checks, monitoring of compliance with the previously defined procedure, among other deviations from the original design. Moreover, in the case of lifting heavy or complex components, monitoring becomes even more critical. Ensuring that lifting procedures comply with safety regulations and that the equipment used is suitable are key to avoiding accidents and ensuring the integrity of the structure.

The importance of due diligence for mechanical and civil engineering

Safety: Mechanical and civil engineering often deals with high-risk situations, where mistakes can result in serious accidents, damage to property or even loss of life. Due diligence aims to identify and mitigate these risks, whether through simulations, inspections, tests or supervision of critical processes. By making sure that all aspects of the project are in line with safety standards, due diligence contributes to preventing incidents and protecting the health and well-being of everyone involved.

Durability: Engineering projects are designed to last for many years. Certifications and inspections ensure that products adhere to specifications and are suitable for the operating conditions of the asset or structures.

Compliance with standards: Technical standards and regulations are established to provide quality and uniformity in industry. In the field of engineering, quality and compliance are crucial to avoid failures, rework and financial losses. Due diligence validates that all aspects of the project, from the selection of materials to the execution of the construction or production processes, comply with standards and technical specifications. This involves checking the quality of materials, the correct application of construction and manufacturing methods, and carrying out tests to ensure that the end result meets the established standards.

Efficiency: Due diligence is not just about quality and safety; it also plays an important role in optimizing processes and reducing costs. By identifying inefficiencies or problem areas during the different phases of the project, due diligence allows for the implementation of improvements that can save time and resources. This is particularly relevant in engineering projects, where small changes can lead to big gains in efficiency and savings.

Meeting deadlines: Engineering projects often have tight deadlines that must be met to avoid delays and negative impacts on schedules. Due diligence helps monitor the physical progress of the project and identify potential obstacles that could affect deadlines. By anticipating problems and proactively resolving challenges, due diligence contributes to on-time project delivery.

Reputation and trust: Companies that obtain manufacturer certifications demonstrate a commitment to quality and excellence. This helps build a solid reputation and establishes the trust of customers and partners.

Conclusion

Due diligence is an indispensable practice in mechanical and civil engineering, offering a set of strategies and processes that guarantee quality, safety and efficiency at all stages of a project. By addressing aspects such as compliance, safety, process improvement and meeting deadlines, due diligence provides a safer, more cost-effective and reliable environment for the execution of engineering projects. Its diligent application aims to bring success and customer satisfaction, as well as contributing to continuous improvement in the field of mechanical and civil engineering.

Se sua empresa busca soluções em diligenciamento de projetos, consulte nossa equipe e conheça nossos serviços. Somos, desde 1993, especialistas em desenvolver soluções de engenharia com foco na promoção de segurança e produtividade às operações de nossos mais de 100 clientes.

Follow our pages on LinkedIn, Facebook e Instagram to keep up with our content.