Introduction

O objetivo principal de um sistema de gestão de integridade estrutural é garantir que os ativos estejam, desde sua implantação até seu descarte, em condição adequada à operação. Em novos ativos, o primeiro passo para isto é a realização de um projeto adequado e devidamente auditado de forma independente. Após a instalação, entretanto, diversas situações podem levar o ativo a condições diferentes do que foi considerado em projeto. Uma gestão de integridade adequada deve ser capaz de identificar tais situações e avaliar se, mesmo nestas circunstâncias, o ativo permanece apto para seu serviço (em inglês “fit for service” ou “fit for purpose”) ou se alguma ação imediata precisa ser tomada.

The identification of these design violations is usually achieved through periodic and special inspections that are able to detect, using appropriate techniques for each type of asset, damage or degradation that could reduce the structural capacity of the asset. In addition, reports of the occurrence of unforeseen situations such as impacts, overloads, operating errors and excessive vibrations are also ways of detecting design violations that need to be analyzed.

When any of these violations are detected, it is up to the integrity management system mentioned above to assess whether the asset in question remains suitable for operation, or whether some immediate action needs to be taken. Fitness for service (FFS) analysis therefore does not represent a specific technique, but rather a type of assessment that can use different techniques, depending on the existing fault in the specific component or situation to be assessed. This assessment forms part of a failure management system, which is an important part of any asset management system.

Os resultados desta análise fornecerão o embasamento técnico necessário sobre a capacidade estrutural residual do ativo para que o responsável pela integridade estrutural possa tomar as decisões necessárias para aquela situação específica, mantendo-se o nível de risco adequado do ativo e, ao mesmo tempo, evitando paradas operacionais desnecessárias. Tais decisões possibilitam também alterar o plano de inspeção do ativo, com base em uma estimativa de vida útil, ou reclassificá-lo indicando novos limites operacionais seguros para a sua condição real. Em alguns casos, a análise de fitness for service pode também ser utilizada para ampliação da vida útil para limites superiores aos inicialmente previstos em projeto.

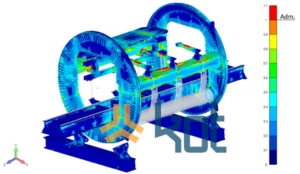

In this article, we will present some examples of fitness for service analysis for non-standard equipment and structures, summarizing the characterization of the problem, the methodology applied and the proposed actions.

Methodology

As mentioned above, FFS analysis does not represent a specific technique, but a type of evaluation that can encompass different techniques, depending on the situation you want to evaluate.

For some types of equipment, there are standards and technical publications that already provide for specific fitness-for-service procedures for known types of defects, such as API 579 for pressure vessels. For some mass-produced equipment, such as aircraft, the manufacturer itself already carries out fitness-for-service analyses for the defects commonly identified in inspections and provides the limits and treatments in the maintenance manuals.

Entretanto, no caso de equipamentos não padronizados e estruturas em geral, ainda que existam publicações técnicas genéricas, não há um procedimento padrão definitivo. Nestes casos, fica a cargo do especialista em integridade estrutural definir quais as técnicas e metodologias mais adequadas para avaliar a capacidade estrutural residual e/ou vida útil do ativo, em cada caso particular.

When defining the appropriate techniques and procedures in a fitness for service analysis of structures and equipment in general, the specialist must take into account various aspects, including:

- Characterization of the fault (type, appearance, dimensions) or damage mechanism;

- Structure material and its properties;

- Type, direction and magnitude of loads;

- Damage evolution rate (stable, variable according to environmental characteristics, variable according to loading characteristics);

- Applicable failure modes;

Based on this information, appropriate testing techniques and simulations must be carried out in order to determine the residual capacity of the structure and its suitability for service conditions. In cases where the residual capacity of the structure does not prove adequate for operation, reinforcements or restorations must be carried out in order to recover the necessary structural capacity. Until these actions are taken, in order to avoid an operational stoppage, a reclassification (de-rating) of the asset can be studied by, for example, reducing capacity or speed or limiting overloading in specific regions.

In the case of damage mechanisms that evolve over time and/or asset operation, such as corrosion degradation or the propagation of fatigue cracks, the fitness for service analysis must determine not only the current residual capacity of the structure, but also the expectation that this degradation will continue over time, in order to define the feasible deadlines for intervention in the structure. This definition provides a basis for adjusting inspection and intervention deadlines to reduce the impact on operations while maintaining an adequate level of asset risk. These adjustments depend on the damage mechanism involved, as well as the characteristics of the asset and the operation.

Corrosion degradation, for example, which involves loss of material, is generally assessed according to the rate of thickness loss calculated from the characteristics of the environment and the determination of minimum admissible limits that maintain adequate residual structural capacity. However, the way in which thickness loss progresses in the component is also dependent on the characteristics of the component itself and the operation. Cross-linked profile structures generally suffer greater corrosion at the ends, implying a reduction in the final dimensions, loss of thickness and even the shape of the profile. This change in shape can be exacerbated by local conditions of exposure to the environment (areas where water accumulates, for example, or areas with degraded protection). In serious situations, this change in shape can even alter the component's failure mode, which must be duly taken into account in the analysis.

Another aspect of great influence in determining inspection and intervention deadlines is the detectability of the failure. In the case of cracks in components subject to variable loading, which can lead to fatigue, determining these deadlines usually involves fracture mechanics analyses to calculate the speed and direction of crack propagation, starting from a certain initial length.

Nestes casos, um aspecto de influência no planejamento das ações são os equipamentos de inspeção disponíveis e a limitação que tais instrumentos possuem para cada tamanho de trinca. Em diferentes materiais, a curva de crescimento de trinca tem formatos distintos. Desta forma, é importante calcular qual o tamanho de trinca teórico, para definir o prazo de inspeção, e avaliar se a detectabilidade do instrumento é adequada. Caso contrário, um resultado incorreto de inspeção pode comprometer toda a análise e as decisões de gestão da integridade por ela embasadas.

Conclusion

From reading this article, it can be concluded that Fitness For Service analysis plays a crucial role in the asset management system. It should also be noted that the study must be carried out by trained professionals, since various aspects, such as the characterization of the failure, the material of the structure and its respective properties, the type, direction and magnitude of the loads, the rate of damage evolution and the applicable failure modes are some of the aspects that must be observed during the assessment.

Acompanhe o Blog da Kot para conferir, em breve, a sequência do artigo, em que serão apresentados exemplos de aplicação do FFS.

Consulte também nossa equipe para maiores informações!

Siga também nossas páginas no LinkedIn, Facebook e Instagram para continuar acompanhando nossos conteúdos.