DISCRETE ELEMENT METHOD (DEM)

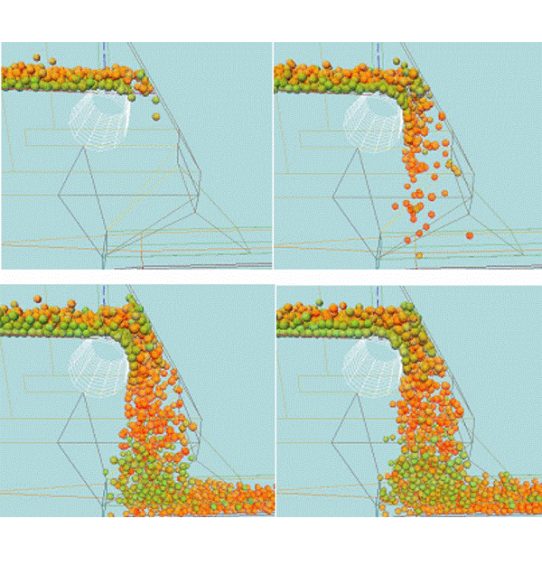

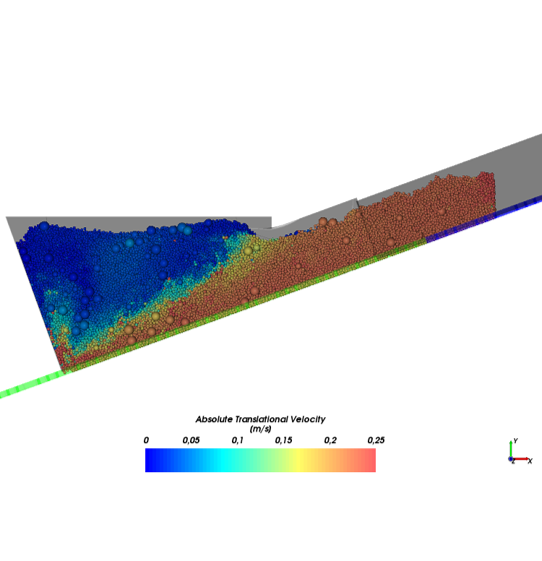

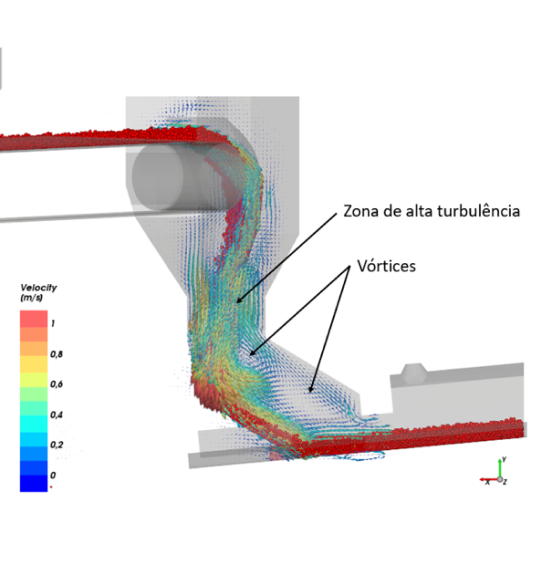

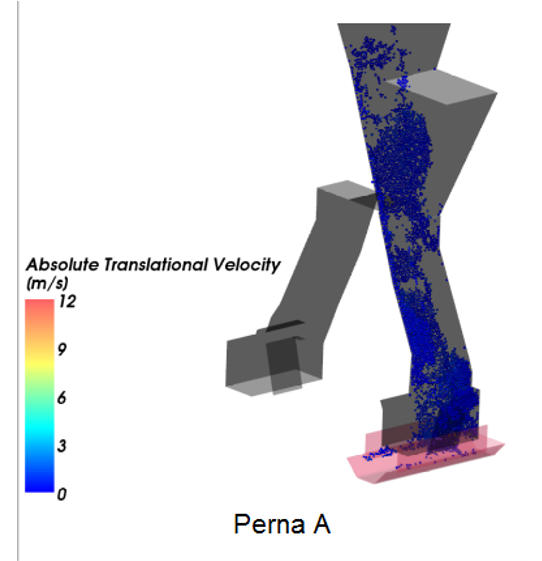

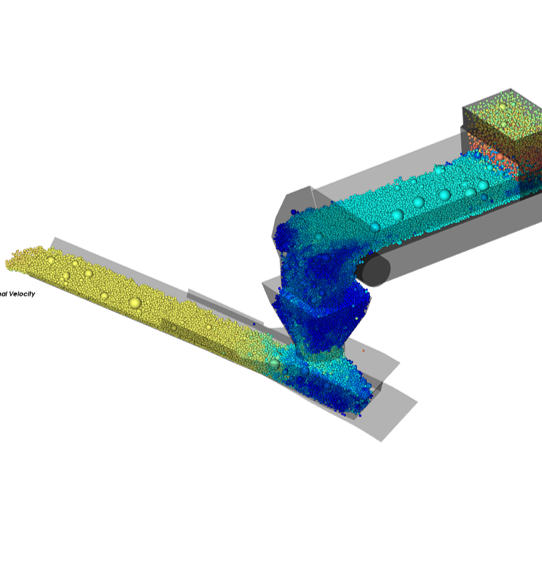

Kot Engineering uses DEM technology (discrete element method) for flow analysis of bulk material on conveyors, transfer chutes, flow diverter, bins, mining trucks and excavators.

Through numerical simulation of bulk material flow it is possible to predict many phenomena that may cause problems to the process, such as structural failures, excessive wear of plates and conveyor belts, chute clogging, spillage, excessive dust, excessive speed and material loss.

Some benefits provided by DEM analysis:

- Prediction of particle flow by considering collisions with existing surfaces such as chutes, belts, diverters and wear plates;

- Precise adjustment of belts, impact tables and other accessories to optimize the flow as needed;

- Considerable extension of the life of belts, since the wear spots are reduced on transfer points.

Learn more about Discrete Element Method (DEM) at: