BULK MATERIAL HANDLING

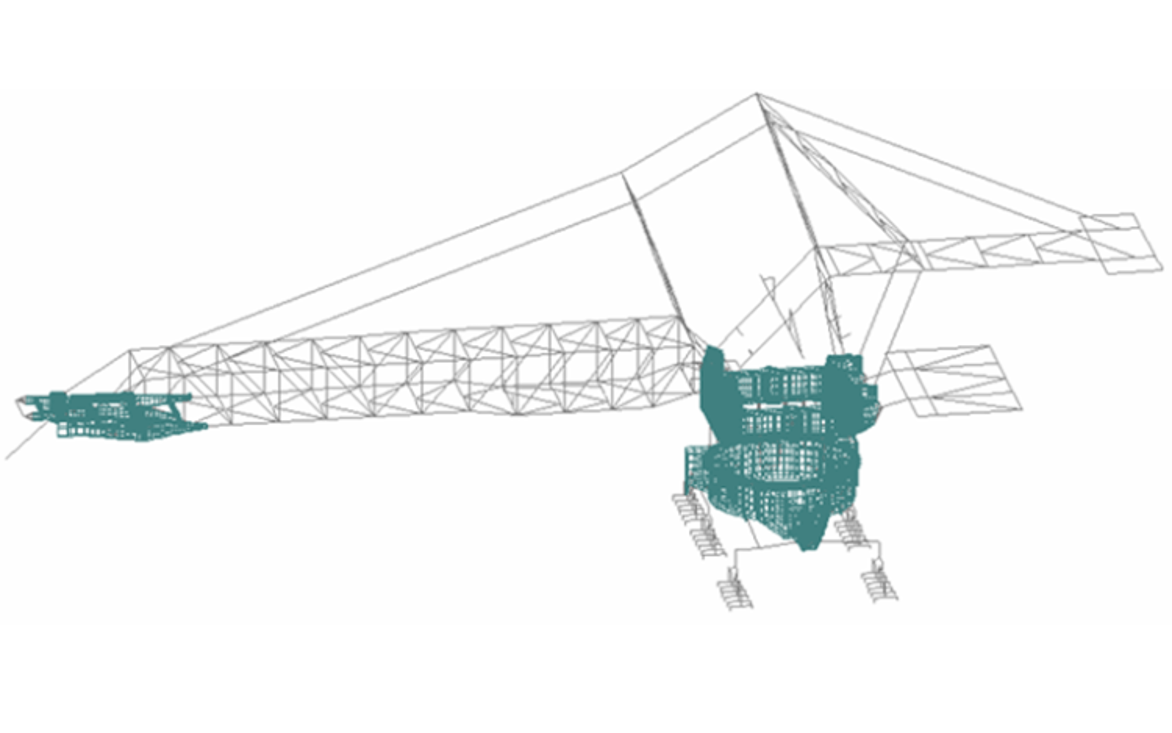

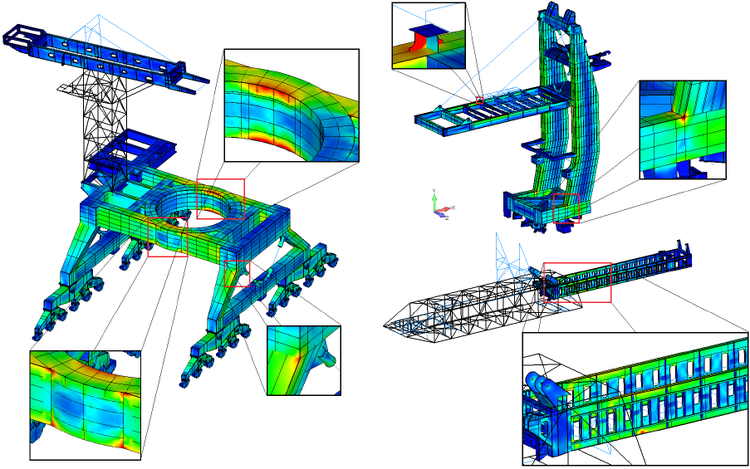

Kot Engineering has extensive experience in the calculation of bulk material handling equipment. Kot analysed hundreds of this kind of stockyard equipment including stackers, reclaimers, wagon tipplers, belt conveyors, ship loaders and ship unloaders.

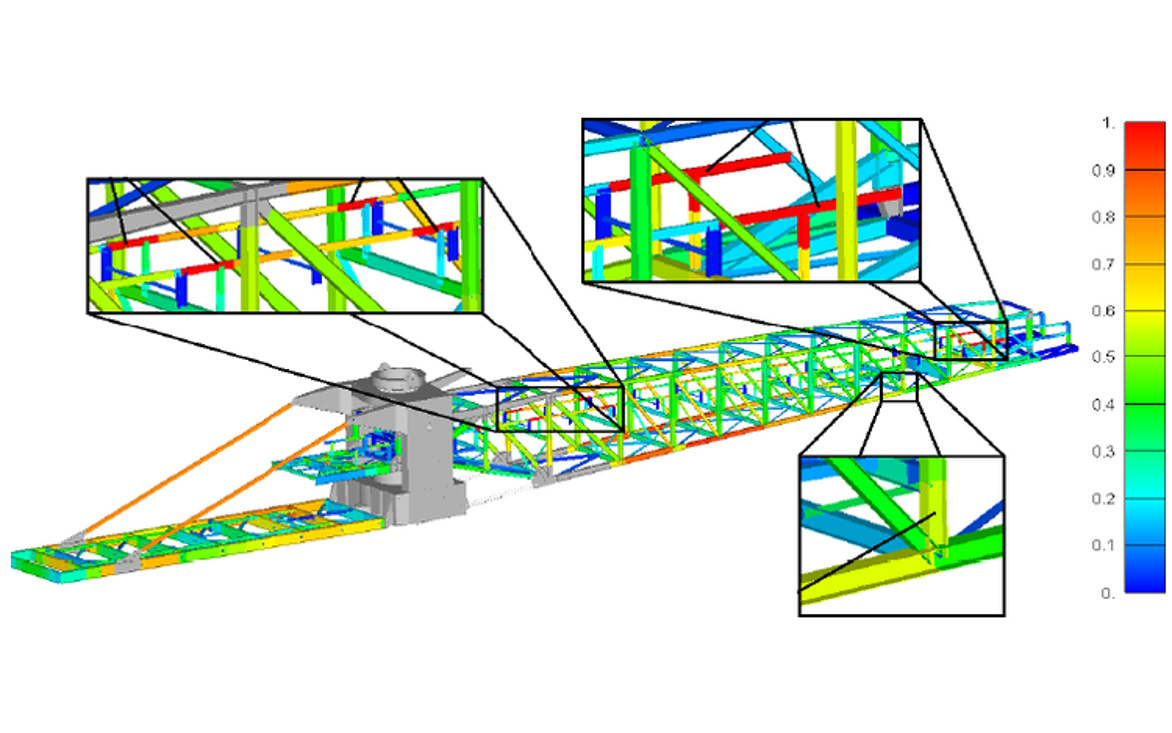

The calculation of these equipments is done following the specifications of ISO-5049, using PROCAL3D software (in-house). The analyses covers all equipment systems including:

- Translation driving system verification;

- Rotation driving system;

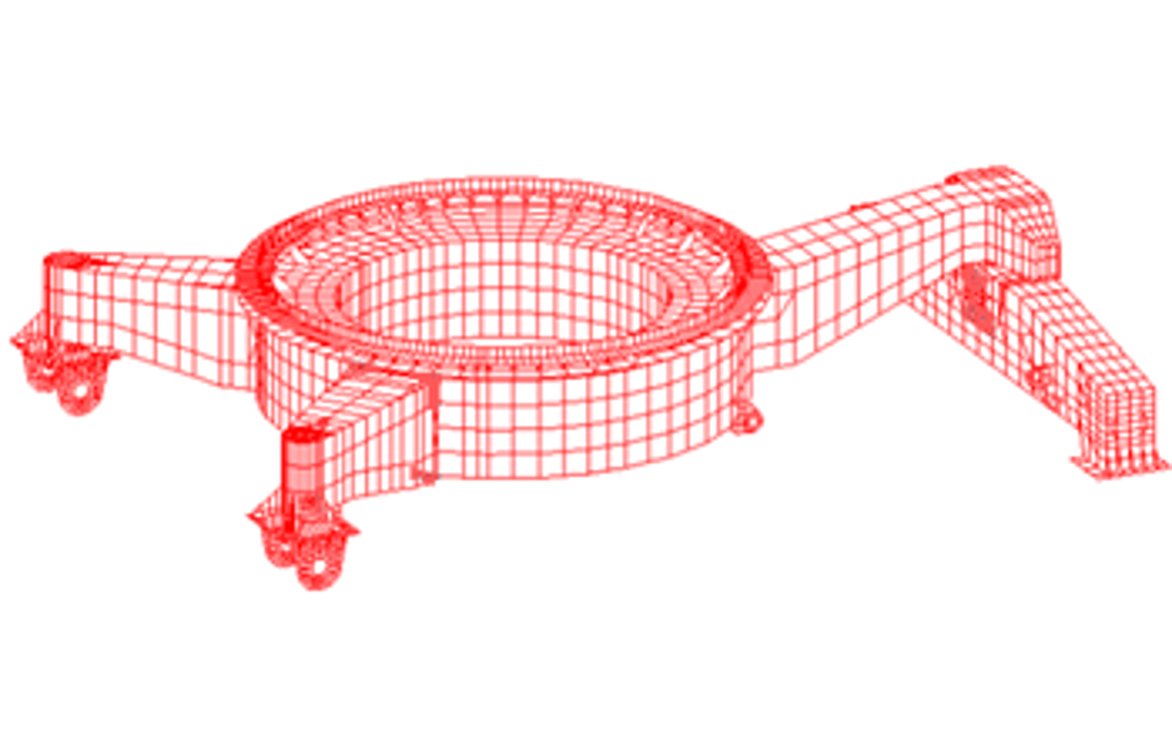

- Turntable bearings and trucks;

- Equipment balancing;

- Boom conveyor calculation;

- Calculation of the pressures in the lifting cylinder;

- Calculation of shock against stock piles and;

- Calculation of bucket wheel.

Kot works in modifications aimed at increasing production capacity and also analyzes possible failures of these equipments.

When analyzing handling machines, the determination of loads in the turning system is essential for the dimensioning of the bearing, especially with respect to its durability. In machines where the upper rotatory part is supported by trucks (instead of bearings), rail damages often occurs, which reduces machine life and causes serious maintenance problems.

Silos are structures designed to store bulk material. They are usually internally coated with plates for wear and corrosion protection. Verifications are based on international standards, such as BS EN 1991-4 and AS-3774. The overall instability of the structure must also be verified, especially under the action of wind loads and when there is a possibility of negative pressures inside the silo as a result of bulk unloading surges.

Learn more about Bulk Material Handling equipment at: